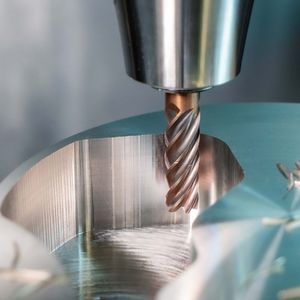

Boring indexable cutting insert CBN

Add to favorites

Compare this product

Characteristics

- Function

- boring

- Material

- CBN

Description

MAPAL tools with guide pads for precision machining bores, reamers and fine boring tools, attribute their outstanding efficiency to direct guiding in the bore by guide pads and the high quality of MAPAL blades. In precision machining bores extraordinary demands are made on cutting materials, coatings, blade geometry and grinding quality. The restricted space in the bore means that the chips must be easy to remove in form and length. With new technology, such as high speed machining or minimal lubrication, easy chip removal is becoming more and more significant. MAPAL blades are being constantly developed and optimised to meet these demands.

To ensure the MAPAL blades are safely held, a clamping groove is used which, when combined with the clamping plate and the adjustment elements, forms a highly positive system. This stability is an important requisite for long tool life and prevents the blades shifting. Typical of an important innovation with significant effect is the MAPAL F chamfer. This narrow chamfer, which runs over the whole area of the clearance angle, provides additional guiding and stabilising in the tools. In addition the MAPAL F chamfer prevents the strong initial wear which frequently appears and the loss in dimension which this causes.

Carbide, Cermet, coatings, PCD and PCBN – the whole range of modern cutting materials is available at MAPAL for every workpiece material and for every cutting task. The latest production technology for manufacturing blades today allows any chipformer and chipbreaker solution to be produced – even with super hard materials such as PCD and PCBN.

Catalogs

No catalogs are available for this product.

See all of MAPAL‘s catalogsRelated Searches

- Milling tool

- Solid milling tool

- Drilling tool

- Steel milling tool

- Clamping milling cutter

- Solid drilling tool

- Metal milling tool

- Milling tool with cylindrical shank

- Insert milling tool

- End mill milling tool

- Coated milling cutter

- Cast iron milling tool

- Indexable cutting insert

- General purpose drill bit

- Cutting milling tool

- Hemispherical milling cutter

- Solid carbide milling tool

- Face milling tool

- Carbide drilling tool

- Roughing milling tool

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.