- Hydraulics - Pneumatics

- Compressor

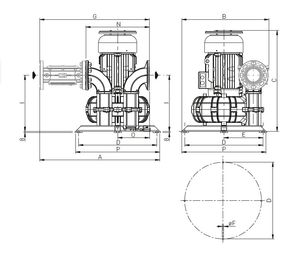

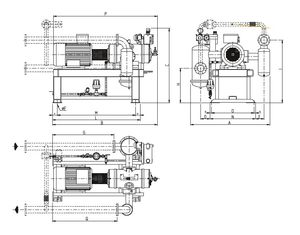

- Rotary vane compressor

- MAPRO International S.p.A.

Rotary vane compressor gaselectrically-poweredfixed

Add to favorites

Compare this product

Characteristics

- Technology

- rotary vane

- Type

- gas

- Power source

- electrically-powered

- Portability

- fixed

- Lubrication

- lubricated

- Application domain

- industrial

Description

MAPRO® rotary vane compressors are positive-displacement machines.

That is, the compression takes place for progressive reduction, inside

the machine body, during rotation, of the gas volume mechanically

displaced from the suction to the discharge port. The discharge

port is opened, on the internal cylindrical surface of the stator, at

an height depending on the foreseen discharge pressure, so that

only the power needed for the actual compression of the gas is

used. It follows that the adiabatic compression efficiency is always

high, and, in general, between the 70 and the 80%.

The tight internal clearances allow, as well, a high volumetric efficiency,

basically unchangeable as blades wear is self-compensating in time.

The power needed for the compression is therefore, in general, lower

than that required from other types of compressors, with consequent

lower operating costs.

Simple and economic maintenance

The small number of parts in motion simplifies the compressor disassembly

and reassembly, so making these operations well less expensive than

compared to other types of positive displacement machines.

A specially provided control rod, allows a quick evaluation, at fixed time

intervals, of the blades wear, without disassembling, even partially, the

machine body so as to enter the compression chamber. It is therefore possible

to plan the blade replacement largely in advance, according to the working

planning of the plant or to the maintenance needs of other equipments,

so simplifying the plant operation and improving its efficiency and economy.

Gas flow without pulsations

Catalogs

No catalogs are available for this product.

See all of MAPRO International S.p.A.‘s catalogsOther MAPRO International S.p.A. products

Compressors and blowers for biogas and natural gas

Related Searches

- Compressor stage

- Air and dry gas compressor

- Positive-displacement compressor

- Fixed compressor

- Industrial compressor

- Electrically-powered compressor

- Oil-injected compressor

- Air blower

- Single-stage blower

- Radial blower

- Compact compressor

- Cooled compressor

- Gas compressor

- Air-cooled compressor

- Ring blower

- Single-stage compressor

- Rotary compressor

- Water-cooled compressor

- Gas blower

- Multi-stage blower

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.