- Hydraulics - Pneumatics

- Compressor

- Natural gas compressor

- MAPRO International S.p.A.

Natural gas compressor biogaselectrically-poweredstationary

Add to favorites

Compare this product

Characteristics

- Type

- natural gas, biogas

- Power source

- electrically-powered

- Portability

- stationary

- Lubrication

- lubricated

- Application domain

- industrial

- Other characteristics

- compact, side-channel

Description

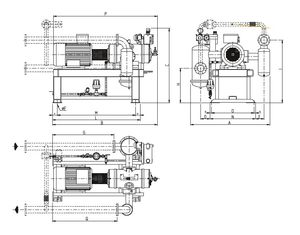

When the gas has to feed a burner or when a variable gas flow

is required, a compact by-pass, directly bolted to the machine

and connecting outlet and inlet ports, is a simple and effective

solution. A suitable overpressure relief valve is fitted inside the

compact by-pass.

When the gas demand decreases, the outlet pressure increases,

and, when the set pressure is reached, the overpressure relief

valve starts to open and by-passes excess gas back to the blower

suction.

In case of low differential pressure, usually the compact bypass

is capable of handling the full capacity of the blower and

thus the machine can continue to run even if the downstream gas

demand is reduced to zero.

For higher differential pressures, where the use of a compact

by-pass is not allowed because of the high temperature increase

when the full capacity of the blower is by-passed back to the

suction, the machine can be supplied with the overpressure relief

valve fitted on an offtake at the outlet side.

In that case the flanged valve discharge could be piped-back to

the blower suction through a by-pass pipe long enough to allow

for sufficient gas cooling.

On request, we can also offer machines equipped with a suitable

gas cooler at the blower outlet, with overpressure relief valve fitted

in an offtake at the cooler outlet, and with the complete by-pass

pipe back to the blower suction side.

We can also offer automatic flow rate adjustment by means of

pneumatic or electrically operated flow control valve, fitted in

the by-pass line and controlled via the client process parameter

discharge gas pressure.

Catalogs

No catalogs are available for this product.

See all of MAPRO International S.p.A.‘s catalogsOther MAPRO International S.p.A. products

Compressors and blowers for biogas and natural gas

Related Searches

- Compressor stage

- Air and dry gas compressor

- Positive-displacement compressor

- Fixed compressor

- Industrial compressor

- Electrically-powered compressor

- Oil-injected compressor

- Air blower

- Single-stage blower

- Radial blower

- Compact compressor

- Cooled compressor

- Gas compressor

- Air-cooled compressor

- Ring blower

- Single-stage compressor

- Rotary compressor

- Water-cooled compressor

- Gas blower

- Multi-stage blower

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.