- Hydraulics - Pneumatics

- Compressor

- Natural gas blower

- MAPRO International S.p.A.

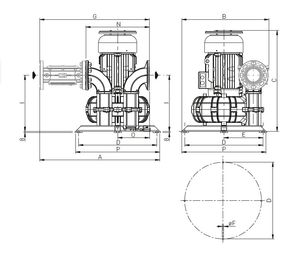

Natural gas blower rotarysingle-stage

Add to favorites

Compare this product

Characteristics

- Type

- for natural gas

- Technology

- rotary

- Number of stages

- single-stage

Description

The Turbotron® is a machine with a peripheral toroidal channel,

similar to side channel blowers, but featuring a revolutionary

impeller and channel design, developed through long

research and tests.

The operating principle, and advantages are the same

as side channel blowers, and yet, the wing contour of

the impeller vanes and the peripheral channel with the

central core allow the achievement of performances

similar to positive displacement machines.

Generalities and construction

features in conformity

with the 94/9/EC

Directive (ATEX)

Construction features are the same as side

channel blowers. But, differently from the side channel machines,

the Turbotron® blowers designed to extract or compress combustible

gases, such as biological or natural gas, are always

manufactured with their own shaft and bearings. Sometimes they

are coupled to the electric motors via a flexible shaft coupling.

In general they are coupled to the electric motors via belt drives.

This is because the Turbotron® for combustible gases is a machine

designed for a wide range of permissible operating speeds of

rotation (from 2000 to 5000 rpm), and therefore, a very large

operating range can be achieved using a single machine size.

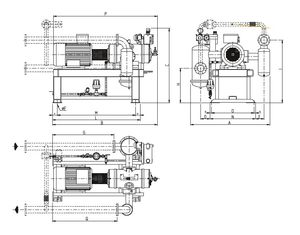

Fields of application - Machines with

gas recirculation - Control via frequency

inverter - Accessories

Everything said for the side channel machines also applies to the

Turbotron® blower with the exception of the compact by-pass

solution which is not available for this type of machine.

The overpressure relief valve, when provided, is always fitted on an

offtake at the discharge side.

Catalogs

No catalogs are available for this product.

See all of MAPRO International S.p.A.‘s catalogsOther MAPRO International S.p.A. products

Compressors and blowers for biogas and natural gas

Related Searches

- Compressor stage

- Air and dry gas compressor

- Positive-displacement compressor

- Fixed compressor

- Industrial compressor

- Electrically-powered compressor

- Oil-injected compressor

- Air blower

- Single-stage blower

- Radial blower

- Compact compressor

- Cooled compressor

- Gas compressor

- Air-cooled compressor

- Ring blower

- Single-stage compressor

- Rotary compressor

- Water-cooled compressor

- Gas blower

- Multi-stage blower

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.