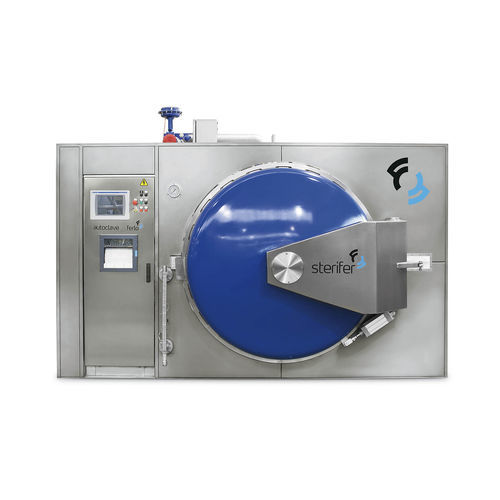

Process autoclave STERIFER sterilizationfor the pharmaceutical industry

Add to favorites

Compare this product

Characteristics

- Laboratory/process

- process

- Applications

- sterilization, for the pharmaceutical industry

Description

Ferlo designs and manufactures autoclaves for the

pharmaceutical industry meeting the highest international

standards of quality for this market.

The construction and design of Ferlo “STERIFER” autoclaves is done following the standards of good manufacturing practices, according to GMP and FDA (Food and Drugs Administration), as well as complying with the applicable national and international standards to date. (IRAM, DNI, ISO, UNE-EN).

Characteristics

Optional manufacturing of 1 door for the loading area and 1 door for the unloading area. The double door equipment is suitable for sterile areas and has security software that prevents simultaneous opening of them.

Pressure system compensated for rain of superheated water applicable to the sterilization of liquids in hermetic containers.

Suitable for using Steam coming from a Central Line.

Fully Programmable Processes.

Touch Screen control panel PLC and programming with multi-channel recorder.

Terminal with printer.

Chamber entirely built in AISI 316 stainless steel.

Design of trays and trolleys that allows automation of the processes of loading and unloading of the same.

The exterior fronts and covers will be built in AISI 304 stainless steel with orbital polishing.

The Autoclave will be mounted on a load-bearing base for correct transfer leveling and anchoring.

Ferlo manufactures and designs a wide range of sterilisation products for the pharmaceutical industry. Ferlo sterilisation systems are suitable for injectable liquids and phials, and comply with the highest international quality standards in the pharmaceutical industry.

Catalogs

Ferlo Autoclaves Sterilisers

10 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.