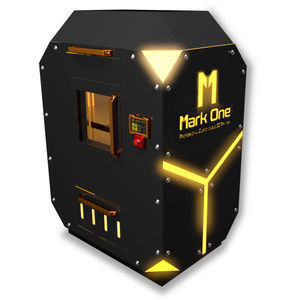

FDM 3D printer MK 333ABSPLAnylon

Add to favorites

Compare this product

Characteristics

- Materials to be printed

- ABS, PLA, nylon, TPU, PETG, PA, carbon fiber reinforced plastic

- Technology

- FDM

- Applications

- for the aerospace industry, for mold manufacturing, for the automotive industry, for the electronics industry, prototyping, dental, medical

- Other characteristics

- high-performance, high-speed, large-format, 3-axis, chemical-resistant, color, with heated enclosure, continuous, on casters, heat/cold-resistant, abrasion-resistant, UV-resistant

- X travel

300 mm

(11.81 in)- Y travel

300 mm

(11.81 in)- Z travel

380 mm

(14.96 in)- Printing nozzle speed

200 mm/s

- Weight

650 kg

(1,433 lb)

Description

MK 333 is the most versatile 3D printer produced by Mark One. Created with new technologies, patented by Mark One, in order to make end-products with the highest degree of freedom in terms of materials’ choice.

« High versatility »

« High performance »

« Continuous production »

The new control board enables a range of features that are unique to the Mark One industrial line and set a new standard for 3D printers. The entire printing process has been designed with the objective of achieving high performance final components. Before the printing process begins, the chamber is heated to a maximum temperature of 80°C. At the same time, the preheating of the materials housed in the reel takes place. The material is extruded onto the nozzle, which can add a maximum temperature of 350°C. Finally, the material is printed on the printing plate which reaches a maximum temperature of 120°C.

Size:120x100x170 cm

Chamber temperature:MAX 80°

Double extruder:MAX 350°

Flat temperature:MAX 120°

FEATURES

AUTOMATIC LEVELING OF THE HEATED PLATEN

for precise and reliable prints.

EXTRUDER WEAR

The machines warn the user when it is time to change the nozzle.

COIL WEIGHT

is monitored by the printer to ensure that there is sufficient material to be successfully completed.

AUTOMATIC TEMPERATURE CONTROL

the printer knows the correct temperature parameters for each material and excludes the possibility of errors.

AUTOMATIC FILAMENT CHANGE

the printer can switch independently from one finished filament reel to another full one.

REAL-TIME RENDERING

of the object that is printed and its progress of realization.

Catalogs

No catalogs are available for this product.

See all of MARK ONE SRL‘s catalogsRelated Searches

- Additive manufacturing machine

- Industrial 3D printing machine

- Plastic 3D printing machine

- Model making 3D printer

- FFF 3D printer

- High-speed 3D printer

- High-performance 3D printing machine

- ABS 3D printing machine

- Large-format 3D printing machine

- PLA 3D printing machine

- Medical additive manufacturing machine

- Dental additive manufacturing machine

- Table-top 3D printer

- TPU 3D printing machine

- Polyamide 3D printer

- PETG 3D printer

- Nylon 3D printing machine

- 3D printer for the aerospace industry

- 3D printer for the automotive industry

- PC 3D printing machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.