- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

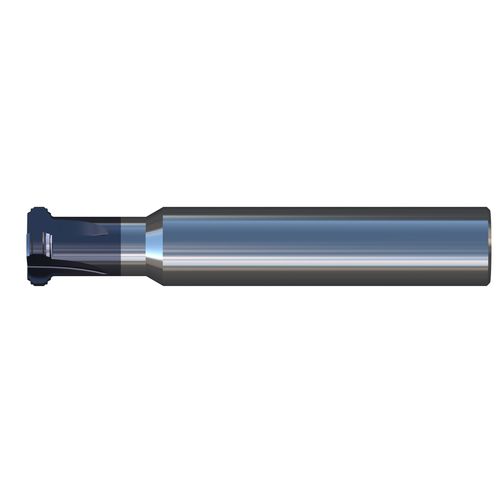

Corner rounding milling cutter corner radiuscircularend mill

Add to favorites

Compare this product

Characteristics

- Geometry

- corner rounding, corner radius, circular, end mill

- Construction

- solid carbide

- Type

- roughing, face, finishing, T-slot, profiling, copying, deburring, angle

- Material

- with TiAlSiN coating, with TiAlCrN coating, DLC-coated, uncoated, high-speed steel

- Treated material

- for steel, for cast iron, for non-ferrous materials, for plastics, for metal, for composites, for wood, for hardened materials, for graphite

- Other characteristics

- HSC, with internal coolant, high-performance, taper shank, 3-flute, 6-flute, 45° helix angle, for small parts, high-precision, cutting edge, high-efficiency, high-speed, 40° helix angle, machine tool, 25° helix angle, 60° helix angle, Weldon, for machine tools, small-diameter, 35° helix angle, high-rigidity, for the aeronautical industry, ISO, 90° helix angle, 4-flute, for countersinking, for aircraft, for special applications, for molds, with measured diameter, 5-flute, aeronautical parts, DIN 335, for graphite machining, for chamfers, for aluminum profiles, deep-cutting, 2-flute, 30° helix angle, with cylindrical shank, cutting, for aeronautical applications, HRC50, conical, for automobiles

- Diameter

Min.: 2 mm

(0.08 in)Max.: 40 mm

(1.57 in)- Length

Min.: 0 mm

(0 in)Max.: 250 mm

(9.84 in)- Rotational speed

Min.: 100 rpm

(628.32 rad.min-1)Max.: 50,000 rpm

(314,159.27 rad.min-1)

Description

T – slots End Mills MASAM are designed based on the T – slots profile and the specified tolerances with different shape of the cutting tool. MASAM T – Slot End Mill is design accordining drawing documentation with wide scale of coating and carbide type for different application.

Solid carbide, clasification ISO, groups K01, K05, K10, K20, K30, K40 depending on the type of machined material MASAM chooses

MACHINED MATERIAL -

T – slots End Mills MASAM is possible to use for machining at least whole material groups under ISO classification – P,M,K,N,S,H

SHANK TYPES -

DIN 6535 HA, HB, HE, HAK14, cylindrical, weldon, or under customer request

TOOL EXECUTION -

Depending machined material or under customer request – coated, polished, rectified

COATING TYPES -

TiN+AlTiN+Si ; TiN+AlTiN+CrAlSiN ; TiAlSiN ; TiAlN ; AlTiN ; CrAlSiN ; TiN ; TiCN ; TiSiN ; DLC ; AlCrBN

Catalogs

No catalogs are available for this product.

See all of MASAM‘s catalogsRelated Searches

- Milling tool

- Solid milling tool

- Drilling tool

- Steel milling tool

- Clamping milling cutter

- Solid drilling tool

- Metal milling tool

- Milling tool with cylindrical shank

- End mill milling tool

- Coated milling cutter

- Cast iron milling tool

- General purpose drill bit

- Cutting milling tool

- Hemispherical milling cutter

- Solid carbide milling tool

- Face milling tool

- Carbide drilling tool

- Roughing milling tool

- Helix angle milling cutter

- Shell-end milling tool

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.