- Packing - Handling - Logistics

- Conveying

- Chain conveyor

- Maschinenbau Kitz GmbH

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

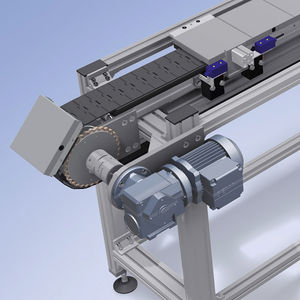

Chain conveyor TKU 2040 serieshorizontalworkpiececompact

Add to favorites

Compare this product

Characteristics

- Technology

- chain

- Form

- horizontal

- Transported product

- workpiece

- Other characteristics

- compact, flexible, indexing

- Maximum load

700 kg

(1,543.236 lb)- Speed

18,000 mm/min

(11.81 in/s)

Description

Interlinking Machining Centres

The TKU 2040 chain conveyor system is especially well suited for cycled, defined and position-oriented supply and removal as well as for interlinking machines and machining centres. The system’s timing can be individually configured to a fixed cycle. The system can be used in the machine tool and plastics industries, throughout the automotive sector and in many other industries.

The TKU 2040 is based on the mk profile system and is modularly constructed, compact, flexible and extremely robust.It is constructed from a timing chain conveyor with 2 roller chains, which permits a total load of up to 700 kg. The conveyor frame consists of two profile sections with gliding assemblies for the chain and the workpiece fixtures. It is available in designs with a predefined width or with an adjustable width. The width adjustment mechanism allows you to transfer workpieces of various sizes.

According to the specific requirements, prisms made out of either polyoxymethylene (POM) or brass can be used as the workpiece fixtures, which are optimal for holding round workpieces. Alternatively you can select profile workpiece carriers, which can be individually equipped with customer-supplied workpiece fixtures.

Catalogs

No catalogs are available for this product.

See all of Maschinenbau Kitz GmbH‘s catalogsRelated Searches

- Maschinenbau Kitz conveyor

- Maschinenbau Kitz belt conveyor

- Maschinenbau Kitz conveyor for the food industry

- Maschinenbau Kitz roller conveyor

- Electric drive conveyor

- Machine foot

- Maschinenbau Kitz chain conveyor

- Food conveyor

- Stainless steel conveyor

- Materials handling conveyor

- Maschinenbau Kitz modular conveyor

- Bulk products conveyor

- Maschinenbau Kitz pallet conveyor

- Maschinenbau Kitz transfer conveyor

- Discharge conveyor

- Threaded foot

- Maschinenbau Kitz box conveyor

- Maschinenbau Kitz curved conveyor

- Carton conveyor

- Maschinenbau Kitz conveyor for the pharmaceutical industry

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.