- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

UV-polymerized adhesive UV24TKLOepoxyfor metalglass

Add to favorites

Compare this product

Characteristics

- Chemical composition

- epoxy

- Type of substrate

- for metal, glass, for plastics

- Number of components

- single-component

- Technical characteristics

- low outgassing, UV-polymerized, chemical-resistant

- Applications

- industrial, sealing, optical, for the aerospace industry

Description

Key Features

• Meets NASA low outgassing requirements

• Superior chemical resistance

• Moderate viscosity

• High dimensional stability

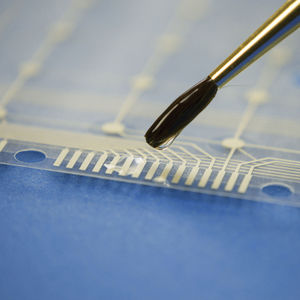

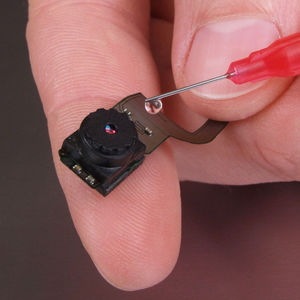

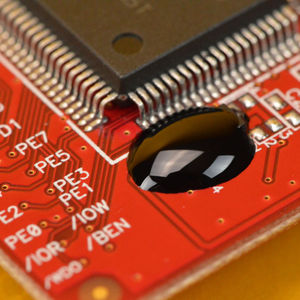

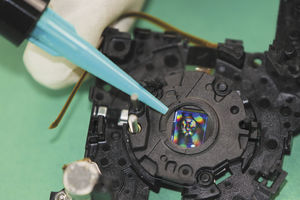

Master Bond UV24TKLO is a one part UV curable epoxy modified formulation for bonding, sealing and encapsulation. It passes the rigorous requirements for low outgassing as per ASTM E-595. Most noteworthy, it has outstanding resistance to chemicals, as described in part below. UV24TKLO has excellent clarity and optical transmission properties. The best wavelengths for curing are 320-365 nm and the energy requirement is 10-40 milliwatts per cm2. This epoxy system is not oxygen inhibited.

UV24TKLO has superb physical strength and electrical insulation properties. The service temperature range is -60°F to +400°F. The UV24TKLO can be cured in thicker sections, up to 1/16 of an inch and can be easily “layered” to higher levels. The low outgassing properties enable this UV to be used in a wide array of optical, electro-optical and vacuum applications that until now have not been possible for UV curable systems. It should be noted that to optimize the outgassing properties, the UV24TKLO should be preheated to approximately 50°C for 15 minutes prior to use and then allowed to cool down to room temperature.

Catalogs

Related Searches

- Master Bond single-component adhesive

- Master Bond metal adhesive

- Master Bond industrial adhesive

- Master Bond plastic adhesive

- Master Bond glass adhesive

- Master Bond epoxy adhesive

- Master Bond dispersion adhesive

- Master Bond bonding adhesive

- Master Bond two-component adhesive

- Master Bond electronic adhesive

- Master Bond ceramic adhesive

- Master Bond sealing adhesive

- Master Bond fast curing adhesive

- Master Bond viscosity adhesive

- Master Bond conductivity adhesive

- Curing unit

- Master Bond rubber adhesive

- UV curing unit

- Transparent glue

- Cyanoacrylate glue

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.