- Products

- Sealing silicone

- Master Bond

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

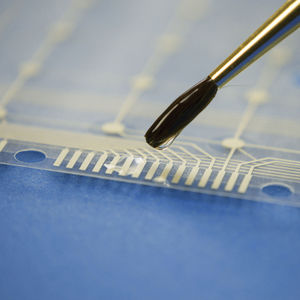

Sealing silicone MasterSil 910Medacetoxy

Add to favorites

Compare this product

Characteristics

- Options

- sealing, acetoxy

Description

Key Features

- Meets USP Class VI requirements

- Passes ISO 10993-5 testing

- Very fast curing

- Paste consistency

- Unsurpassed performance profile

- Excellent sterilization resistance

MasterSil 910Med is a one part silicone for bonding, sealing and coating primarily for medical devices. It passes both USP Class VI testing and ISO cytotoxicity specifications. As an acetoxy type system, it bonds exceptionally well to a wide variety of substrates including metals, composites, ceramics, glass as well as many rubbers and plastics. MasterSil 910Med can resist the most aggressive types of thermal cycling as well as mechanical and thermal shock. Typical of one part silicones, the curing mechanism is based on the humidity level. The higher the humidity, the faster the cure and thinner sections cure more quickly than thicker ones. MasterSil 910Med is a fast curing system and depending upon the application, the tack free time can range from 10-20 minutes. It withstands liquid sterilants, gamma radiation and EtO very well. Its service temperature range is -75°F to +400°F. One particularly useful product property is its ability to adhere well to silicone substrates. MasterSil 910Med can be used in a wide array of medical device applications where the acetoxy type cure is not an issue and optimum product properties are required. It should be emphasized that for biocompatibility testing, a full cure of at least 7 days is recommended.

Catalogs

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.