- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

UV-polymerized adhesive UV22DC80-1epoxyfor metalfor plastics

Add to favorites

Compare this product

Characteristics

- Chemical composition

- epoxy

- Type of substrate

- for metal, for plastics, glass, for rubber, for ceramics, for composite materials

- Number of components

- single-component

- Technical characteristics

- low-viscosity, low outgassing, UV-polymerized, heat-cured, dual-curing, electrically insulating, chemical-resistant, abrasion-resistant

- Applications

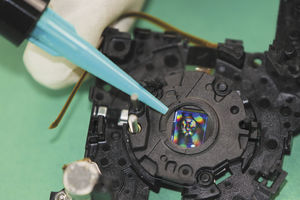

- industrial, optical, for the aerospace industry, for bonding, for photovoltaic applications

Description

Key Features

- Low viscosity

- Minimal shrinkage upon curing

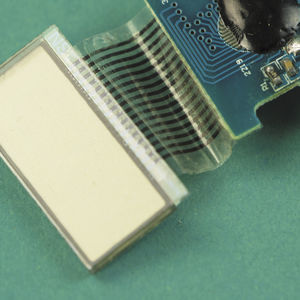

- Superb optical clarity

- Cures at 80°C in shadowed out areas

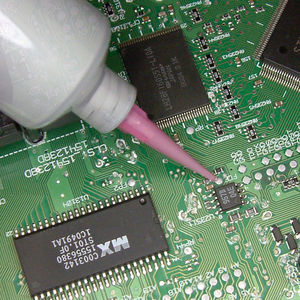

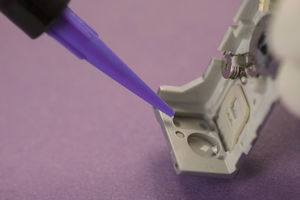

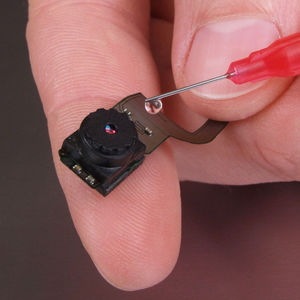

Master Bond UV22DC80-1 is a nanosilica filled, dual cure epoxy based system. It is formulated to cure readily upon exposure to UV light and most importantly it will crosslink in shadowed out areas with the addition of heat. The logic in developing this kind of product is that UV curables will cross-link rapidly and thoroughly upon exposure to the light, but it will not cure in areas where the material is not exposed to the light. Having a dual cure mechanism allows those areas not exposed to the light being curable with the addition of heat. The thermal part of the cure is achieved at a user friendly 80°C (particularly when working with plastics). Dual cure systems are particularly useful for rapidly fixturing parts with the UV portion of the cure and then finishing the process by heating.

This lower viscosity system features a cationic cure mechanism (for the UV portion). This combined with being a nano filled system confers an exceptionally low shrinkage and outstanding dimensional stability. UV22DC80-1 is not oxygen inhibited. After polymerizing, it has many advantageous properties. It bonds well to a wide variety of substrates including metals, glass, ceramics and most plastics. UV22DC80-1 has very good chemical resistance to many acids, bases, fuels and solvents. It is a superb electrical insulator, also it is able to withstand rigorous thermal cycling. The service temperature range is -100°F to +350°F.

VIDEO

Catalogs

Related Searches

- Master Bond single-component adhesive

- Master Bond metal adhesive

- Master Bond industrial adhesive

- Master Bond plastic adhesive

- Master Bond glass adhesive

- Master Bond epoxy adhesive

- Master Bond dispersion adhesive

- Master Bond bonding adhesive

- Master Bond two-component adhesive

- Master Bond electronic adhesive

- Master Bond ceramic adhesive

- Master Bond sealing adhesive

- Master Bond fast curing adhesive

- Master Bond viscosity adhesive

- Master Bond conductivity adhesive

- Curing unit

- Master Bond rubber adhesive

- UV curing unit

- Transparent glue

- Cyanoacrylate glue

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.