- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Two-component adhesive EP31epoxyfor metalglass

Add to favorites

Compare this product

Characteristics

- Chemical composition

- epoxy

- Type of substrate

- for metal, glass, for rubber, for ceramics

- Number of components

- two-component

- Technical characteristics

- low-viscosity, electrically insulating, shear strength, chemical-resistant, high peel strength

- Applications

- industrial, for electronics, sealing, for coating, for OEM, optical, for the aerospace industry

Description

Key Features

- Convenient handling

- Excellent structural adhesive

- Combines low viscosity and optical clarity

- Provides superior electrical insulation values

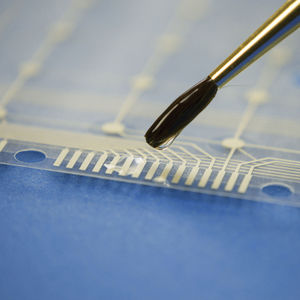

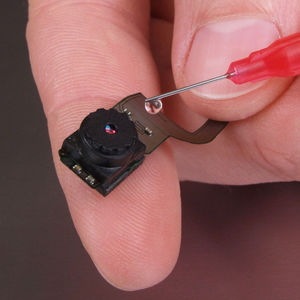

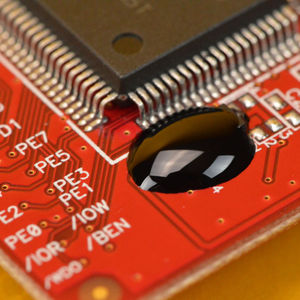

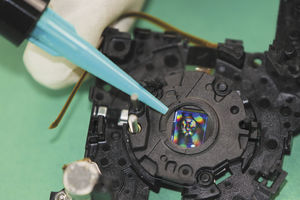

Master Bond EP31 is a two part epoxy system used primarily for bonding, but is also serviceable as a coating, sealing and encapsulation agent. The processing is relatively easy and straightforward with a forgiving mix ratio of 100 to 30 by weight. It cures readily at room temperature or more rapidly at elevated temperatures. At ambient temperatures, it cures in about 1-2 days, and at 200°F, in about 2-3 hours. To optimize properties, an overnight cure at room temperature followed by 2-3 hours at 150-200°F is desirable. Upon cross linking, EP31 has toughness and resiliency allowing it to withstand aggressive thermal cycling. Most prominent is its remarkable tensile lap shear and peel strength (summarized below). It bonds well to a wide variety of substrates, including metals, composites, glass, rubber, ceramics and many plastics. Some other desirable attributes include chemical resistance to water, oils and fuels; very good optical clarity and low shrinkage upon curing. It is a first class electrical insulator, which, when combined with its good flow properties, enables it to be used for smaller potting applications. The service temperature range is -60°F to +250°F. It is also available in a non-drip version called EP31ND. This robust product profile allows EP31 to be considered for use in aerospace, electronic, optical, opto-electronic, specialty OEM and related industries.

Catalogs

Related Searches

- Master Bond single-component adhesive

- Master Bond metal adhesive

- Master Bond industrial adhesive

- Master Bond plastic adhesive

- Master Bond glass adhesive

- Master Bond epoxy adhesive

- Master Bond dispersion adhesive

- Master Bond bonding adhesive

- Master Bond two-component adhesive

- Master Bond electronic adhesive

- Master Bond ceramic adhesive

- Master Bond sealing adhesive

- Master Bond fast curing adhesive

- Master Bond viscosity adhesive

- Master Bond conductivity adhesive

- Curing unit

- Master Bond rubber adhesive

- UV curing unit

- Transparent glue

- Cyanoacrylate glue

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.