- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Epoxy adhesive EP17HTDA-1for metalfor ceramicsfor plastics

Add to favorites

Compare this product

Characteristics

- Chemical composition

- epoxy

- Type of substrate

- for metal, for ceramics, for plastics, for composite materials

- Number of components

- single-component

- Technical characteristics

- low outgassing, electrically insulating, thermally-conductive, high-temperature, chemical-resistant

- Applications

- for electronics, sealing

Description

Key Features

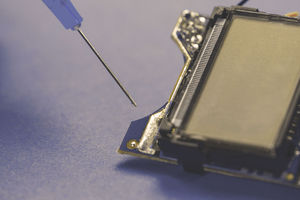

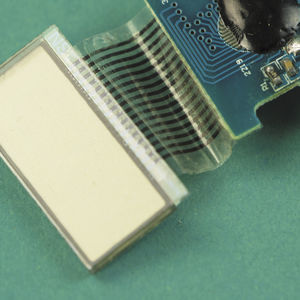

- Ideal for die attach applications

- Resists temperatures up to +600°F

- Meets MIL-STD-883J Section 3.5.2 for thermal stability

- Meets NASA low outgassing specifications

Master Bond EP17HTDA-1 is a one component, heat cured epoxy system primarily for die attach applications as well as more conventional bonding and sealing. It requires no mixing and cures readily at 300-350°F. Typical curing schedules are 2-3 hours at 300°F or 1-2 hours at 350°F. Curing in this manner will optimize properties. EP17HTDA-1 has the ideal consistency and flow for die attach applications.

This epoxy system features excellent physical properties, superb electrical insulation along with good thermal conductivity, even at elevated temperatures. This system is also distinctive in that it has a relatively low exotherm upon curing. EP17HTDA-1 is 100% reactive and contains no solvents or diluents. EP17HTDA-1 bonds well to similar and dissimilar substrates such as metal, ceramics, plastics and composites. It has a noteworthy resistance to many chemicals including acids, bases, salts, fuels, oils and many solvents. Significantly, it has minimal shrinkage upon curing. Its service temperature range is from -80°F to +600°F. Since it passes NASA low outgassing, it can be used in vacuum type situations and other applications where that requirement is needed. EP17HTDA-1 is used primarily as a die attach and adhesive/sealant in electronic and related applications, where high temperature resistance, good electrical insulation properties and thermal conductivity are desirable.

Catalogs

No catalogs are available for this product.

See all of Master Bond‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.