- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Dual-curing adhesive UV22DC80-10Fepoxyfor metalglass

Add to favorites

Compare this product

Characteristics

- Chemical composition

- epoxy

- Type of substrate

- for metal, glass, for ceramics, for plastics

- Number of components

- single-component

- Technical characteristics

- low-viscosity, low outgassing, UV-polymerized, heat-cured, dual-curing, electrically insulating, chemical-resistant

- Applications

- for electronics, for OEM, optical, for the aerospace industry

Description

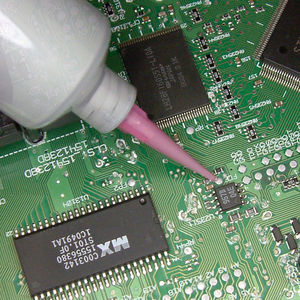

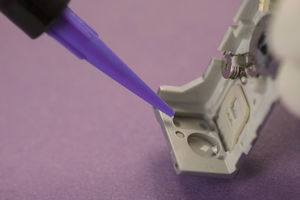

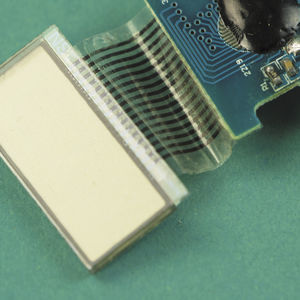

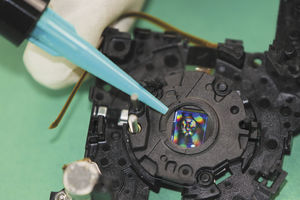

Master Bond UV22DC80-10F is a nanosilica filled, UV dual cure system with high dimensional stability. It may be used for high tech aerospace, electronics, optical and specialty OEM applications.

Key Features

• Thixotropic low viscosity

• Meets NASA low outgassing specifications

• Minimal shrinkage upon curing

• Cures at 80°C in shadowed out areas

Master Bond UV22DC80-10F is a nanosilica filled, UV dual cure system. The secondary cure is accomplished by adding heat, with the minimum temperature being 80°C. Essentially, this epoxy based system will cure readily upon exposure to UV light and if there are any shadowed out areas, heating at 80°C will complete the cure. The 80°C curing feature is particularly useful given the sensitivity of many plastics to elevated temperatures.

UV22DC80-10F’s consistency can best be described as thixotropic, low viscosity. It dispenses readily, but it is not as free flowing as other systems. This UV is a cationic type cure and is not oxygen inhibited. It bonds well to a wide variety of substrates including metals, glass, ceramics and most plastics. UV22DC80-10F has very good chemical resistance to many acids, bases, fuels and solvents. It is a superb electrical insulator, also it is able to withstand rigorous thermal cycling. The service temperature range is -100°F to +350°F. Being a nanosilica filled system, it has exceptionally low shrinkage upon curing and stellar dimensionally stability.

Catalogs

No catalogs are available for this product.

See all of Master Bond‘s catalogsRelated Searches

- Master Bond single-component adhesive

- Master Bond metal adhesive

- Master Bond industrial adhesive

- Master Bond plastic adhesive

- Master Bond glass adhesive

- Master Bond epoxy adhesive

- Master Bond dispersion adhesive

- Master Bond bonding adhesive

- Master Bond two-component adhesive

- Master Bond electronic adhesive

- Master Bond ceramic adhesive

- Master Bond sealing adhesive

- Master Bond fast curing adhesive

- Master Bond viscosity adhesive

- Master Bond conductivity adhesive

- Curing unit

- Master Bond rubber adhesive

- UV curing unit

- Transparent glue

- Cyanoacrylate glue

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.