- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Epoxy adhesive EP3UF-1for metalfor ceramicsfor plastics

Add to favorites

Compare this product

Characteristics

- Chemical composition

- epoxy

- Type of substrate

- for metal, for ceramics, for plastics, for composite materials

- Number of components

- single-component

- Technical characteristics

- low-viscosity, electrically insulating, thermally-conductive, chemical-resistant, water-resistant

- Applications

- for electronics

Description

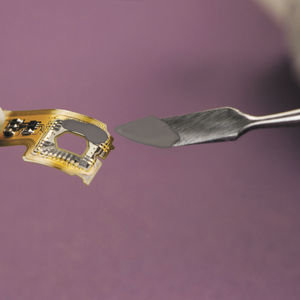

Master Bond EP3UF-1 is a one component, highly flowable epoxy for bonding and underfill applications. It is easily cured at elevated temperatures as low as 250°F. It is not premixed and frozen and has unlimited working life at room temperatures. Curing is simple and straightforward; 20-30 minutes at 250°F or 10-15 minute at 300°F. EP3UF-1 is distinguished by being thermally conductive and electrically insulative by using very special filler material with ultra small particle sizes. These granules allow EP3UF-1 to be used as an underfill in spaces as small as 10-15 microns wide. As an underfill system, EP3UF-1 has high mechanical strength properties, outstanding dimensional stability and low shrinkage upon curing.

EP3UF-1 also is a highly useful thermally conductive adhesive. Since the filler is thermally conductive and the particle size very small, as mentioned above, it can be applied in thin bond lines of 10-15 microns. This, in effect, lowers the thermal resistance and effectively increases the heat transfer properties of the system. For example, with a typical thermally conductive filler, a reasonable bond line thickness is about 50 microns. With this epoxy, the thermal resistance would be 30-50 x 10-6 K•m2/W. However, when an epoxy such as EP3UF-1 is applied in thickeness of 10-15 microns, the thermal resistance drops to 5-7 x 10-6 K•m2/W. Obviously, this is helpful in managing heat related issues. Some other noteworthy attributes of this system include the ability to bond well to a variety of substrates such as metals, composites, ceramics and many plastics. It has reasonably good resistance to a wide variety of waters, oils and fuels.

Catalogs

No catalogs are available for this product.

See all of Master Bond‘s catalogsRelated Searches

- Master Bond single-component adhesive

- Master Bond metal adhesive

- Master Bond industrial adhesive

- Master Bond plastic adhesive

- Master Bond glass adhesive

- Master Bond epoxy adhesive

- Master Bond dispersion adhesive

- Master Bond bonding adhesive

- Master Bond two-component adhesive

- Master Bond electronic adhesive

- Master Bond ceramic adhesive

- Master Bond sealing adhesive

- Master Bond fast curing adhesive

- Master Bond viscosity adhesive

- Master Bond conductivity adhesive

- Curing unit

- Master Bond rubber adhesive

- UV curing unit

- Cyanoacrylate glue

- Transparent glue

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.