- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

LED-cured adhesive LED405Medpolymerglasssingle-component

Add to favorites

Compare this product

Characteristics

- Chemical composition

- polymer

- Type of substrate

- glass

- Number of components

- single-component

- Technical characteristics

- LED-cured, dimensionally stable, electrically insulating, chemical-resistant

- Applications

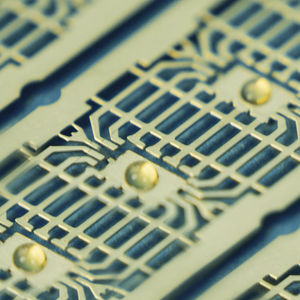

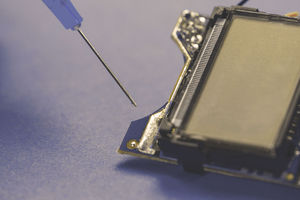

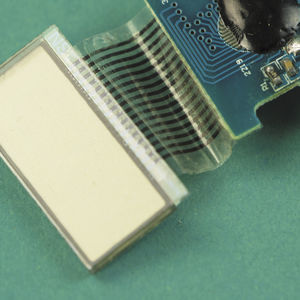

- industrial, optical, medical

Description

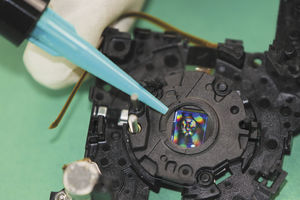

Master Bond LED405Med is a one part system that cures upon exposure to a 405 nm LED light without requiring a UV light source. It will cure without any oxygen inhibition. Its most special feature is that its main constituent is a nanofilled resin. This results in lower shrinkage upon curing and greater dimensional stability. By using LED light and not UV, it is intrinsically less hazardous and more user friendly.

Master Bond LED405Med requires no mixing and cures rapidly upon exposure to 405 nm LED light. The speed of cure depends upon the intensity of the light source, the thickness of the layer, and the distance of the light source from the material being cured. Realistically, the light intensity should be 1-4 watts/cm2. Master Bond strongly advises end users to consult with their LED light provider in order to choose the best light source.

LED405Med will typically cure in 30-45 seconds in thinner sections, while thicker sections will take longer to cure. LED405Med bonds well to a wide variety of substrates including metals, plastics and glass. It is a superior electrical insulator and is resistant to water, several acids and bases, as well as oils and fuels. LED405Med resists many sterilization methods such as gamma, EtO and radiation. It has a particular affinity for acrylics, polycarbonates, and glass.

Product Advantages

• One component system needs no mixing

• Cures by LED light, UV light not required

• Nanofilled system

• Unsurpassed low shrinkage upon curing

• Reasonably good physical strength properties

• Superb dimensional stability

Catalogs

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.