- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Epoxy adhesive EP21LV for metalglassfor rubber

Add to favorites

Compare this product

Characteristics

- Chemical composition

- epoxy

- Type of substrate

- for metal, glass, for rubber, for ceramics, for plastics

- Number of components

- two-component

- Technical characteristics

- low-viscosity, electrically insulating, chemical-resistant

- Applications

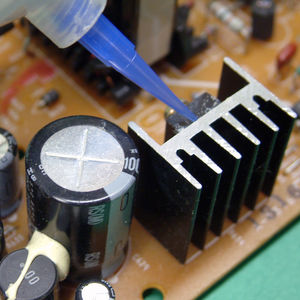

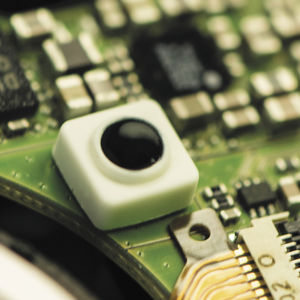

- industrial, for electronics, sealing, for coating, for OEM, for the aerospace industry

Description

Key Features

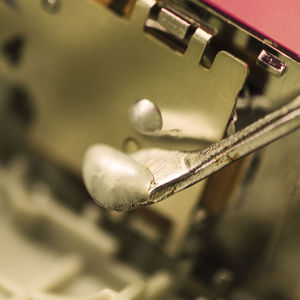

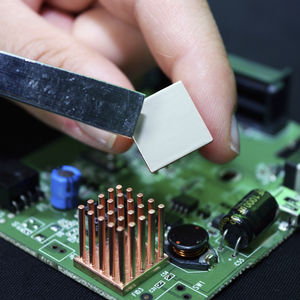

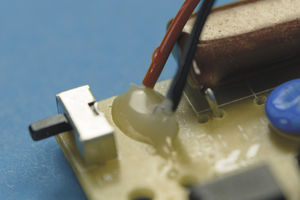

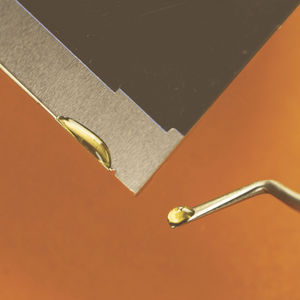

■ Suitable for bonding, sealing, coating, encapsulation and casting

■ Adjustable rigidity and flexibility by altering the mix ratio

■ Conforms to FDA Chapter 1, Section 175.105 for indirect food applications

■ Cures at room temperature

■ Serviceable from -65°F to +250°F

Master Bond EP21LV is a two component, low viscosity epoxy resin system for high performance bonding, sealing, coating, encapsulation and casting. It is formulated to cure readily at room temperature or more quickly at elevated temperatures. It has a very forgiving one to one mix ratio by weight or volume. In fact, EP21LV has the unusual characteristic of being able to adjust the properties of the cured system by altering the mix ratio. Adding more of Part A (e.g. a two to one mix ratio) gives a more rigid cure, for enhanced machinability. While adding more of Part B (e.g. a one to two mix ratio) gives a more forgiving cure, for greater impact resistance. EP21LV produces high strength, durable bonds which hold up well to thermal cycling and resists many chemicals including water, oils, fuels, acids, bases and salts. It is serviceable over the wide temperature range of -65°F to +250°F. It bonds well to a variety of substrates including metals, glass, ceramics, wood, rubbers and many plastics. Once cured, EP21LV is an outstanding electrical insulator. This, coupled with its low viscosity, makes it an excellent encapsulating and potting epoxy. It meets FDA requirements for indirect food contact. EP21LV contains no solvents or diluents. While the standard color of the cured material is amber-clear, a wide variety of additional color choices are also available.

Catalogs

Related Searches

- Master Bond single-component adhesive

- Master Bond metal adhesive

- Master Bond industrial adhesive

- Master Bond plastic adhesive

- Master Bond glass adhesive

- Master Bond epoxy adhesive

- Master Bond dispersion adhesive

- Master Bond bonding adhesive

- Master Bond two-component adhesive

- Master Bond electronic adhesive

- Master Bond ceramic adhesive

- Master Bond sealing adhesive

- Master Bond fast curing adhesive

- Master Bond viscosity adhesive

- Master Bond conductivity adhesive

- Curing unit

- Master Bond rubber adhesive

- UV curing unit

- Transparent glue

- Cyanoacrylate glue

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.