- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Epoxy adhesive EP21TDC-4 for metalglassfor rubber

Add to favorites

Compare this product

Characteristics

- Chemical composition

- epoxy

- Type of substrate

- for metal, glass, for rubber, for ceramics, for plastics, for composite materials

- Number of components

- two-component

- Technical characteristics

- elastic, heat-cured, electrically insulating, high peel strength

- Applications

- industrial, sealing, for coating, for OEM, for the aerospace industry

Description

Key Features

■ High peel strength

■ Outstanding adhesion to rubbers

■ Excellent thermal cycling resistance

■ Withstands 1,000 hours 85°C/85% RH

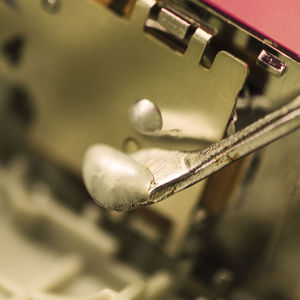

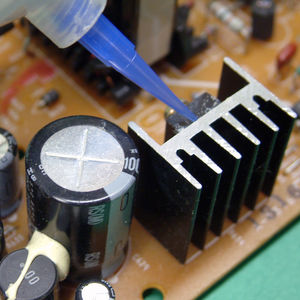

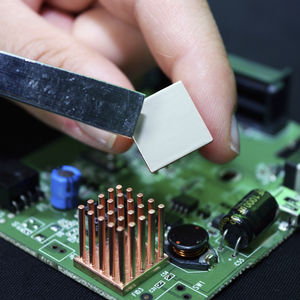

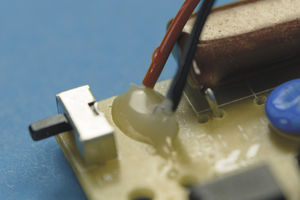

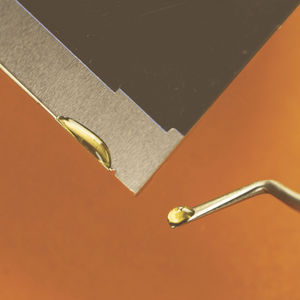

Master Bond EP21TDC-4 is a two component, very flexible epoxy for high performance bonding, sealing and coating. It has a non-critical one to four mix ratio by weight. This system has a relatively long open time of 90-120 minutes for a 100 gram mass. EP21TDC-4 has a room temperature cure that can be accelerated by adding heat. The optimum cure schedule is 12 hours at 75°F followed by 3-5 hours at 140-160°F. An unusual feature of this product is that straight heat curing results in a product that is slightly softer (50-60 Shore A), than the one with the optimum cure (75-85 Shore A). The cured system has a peel strength greater than 25-35 pli and an elongation of over 200%. EP21TDC-4 bonds well to a wide variety of metals, plastics and especially rubbers. In fact, it usually adheres well to rubbers such as neoprene, nitrile, SBR and occasionally EPDM, although surface treatment of the rubbers (especially EPDM) will allow for better adhesion. EP21TDC-4 has excellent electrical insulation properties along with good chemical resistance to oils and water. The epoxy has superior resistance to rigorous thermal cycling along with an outstanding ability to resist mechanical shock and vibration. The color of Part A is clear and Part B is amber-brown. It has an operating temperature range of -100°F to +250°F. EP21TDC-4 can be used in aerospace, electrical, OEM, electronic as well as repair and maintenance applications, where the special properties described above are desirable.

Catalogs

No catalogs are available for this product.

See all of Master Bond‘s catalogsRelated Searches

- Master Bond single-component adhesive

- Master Bond metal adhesive

- Master Bond industrial adhesive

- Master Bond plastic adhesive

- Master Bond glass adhesive

- Master Bond epoxy adhesive

- Master Bond dispersion adhesive

- Master Bond bonding adhesive

- Master Bond two-component adhesive

- Master Bond electronic adhesive

- Master Bond ceramic adhesive

- Master Bond sealing adhesive

- Master Bond fast curing adhesive

- Master Bond viscosity adhesive

- Master Bond conductivity adhesive

- Curing unit

- Master Bond rubber adhesive

- UV curing unit

- Cyanoacrylate glue

- Master Bond composite material adhesive

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.