- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Polymer adhesive X21for metalfor rubberfor ceramics

Add to favorites

Compare this product

Characteristics

- Chemical composition

- polymer

- Type of substrate

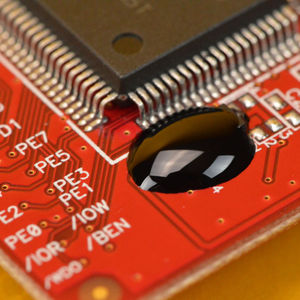

- for metal, for rubber, for ceramics, for plastics, for composite materials

- Number of components

- single-component

- Technical characteristics

- low-viscosity, heat-cured

- Applications

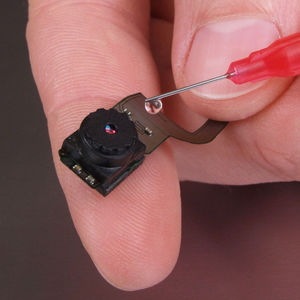

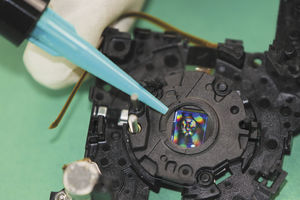

- industrial, for OEM, optical, for the aerospace industry, medical

Description

Key Features

• One component, easy to apply

• Can be used as a primer or adhesive

• Cures tough, not rigid

• Cures at ambient or elevated temperatures

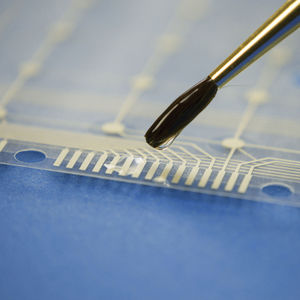

Master Bond X21 is a specially formulated one component system for bonding and priming polyolefinic surfaces. X21 is a very low viscosity(<250 cps) solvent based system that is easy to apply and process. Most often, it is used as a primer to promote adhesion of polyolefinic substrates to other kinds of materials, such as metals, ceramics, composites and other kinds of plastics. When employed as a primer, X21 is applied in a very thin layer on to the polyolefinic piece and the solvent allowed to evaporate. This will take place typically in 2-4 hours and can be greatly accelerated by adding heat (15-30 minutes at 150-200°F). After the surface is primed in this manner, an epoxy or silicone is prepared and applied to the substrates, and then allowed to cure. When used in this fashion, X21 is, in essence, a bonding promoter, allowing adhesion to this low energy type of plastic (polyolefin) in a process that is relatively simple and straightforward.

X21 can also be used as an adhesive for bonding one polyolefin to another one. When used in this manner, a thin layer of X21 is applied to each surface. The surfaces are then mated and the solvent is allowed to evaporate. When cured at room temperature, it will generally set up in 30-45 minutes with full cures in 12-24 hours. If cured at 150°F the curing time will be 1-2 hours. When being used as an adhesive, the maximum area of effectiveness for X21 is about 1 square inch. When used as a primer, there is no such limitation in the size of the pieces.

Catalogs

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.