- Machine-tools

- Machining Center

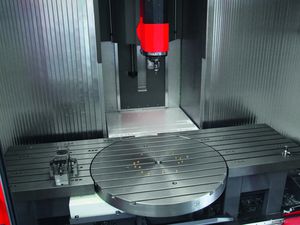

- 3-axis machining center

- matec Maschinenbau

3-axis CNC machining center verticalcolumn typerotating table

Add to favorites

Compare this product

Characteristics

- Number of axes

- 3-axis

- Spindle orientation

- vertical

- Structure

- column type, rotating table

- Spindle mount

- SK40, HSK-63

- Number of tool stations

- 48 tools

- Other characteristics

- high-precision, modular

- X travel

3,000 mm

(118.11 in)- Y travel

825 mm

(32.48 in)- Z travel

1,100 mm

(43.31 in)- Rotational speed

15,000 rpm

(94,248 rad.min-1)- Power

30 kW

(40.79 hp)- Work feed X-axis

48,000 mm/min

(31 in/s)- Work feed Y-axis

48,000 mm/min

(31 in/s)- Work feed Z-axis

48,000 mm/min

(31 in/s)

Description

Complete machining through additive machining units and integrated automation. Technical data based on modular group

Concept

With this machine concept, all process steps from

feeding the bar profile, 6-sided machining in two

clamping positions and automatic unloading are

combined in a single machine.

This results in a fully automatic production process.

This in turn guarantees the highest precision and

repeatability over the entire production period.

The concept is thus not only able to optimise

production, but also to generate savings in the mid

double-digit range.

Technical details

Moving column machining centre with swivel head

Automatic bar feeder

CNC rotary table, horizontal, with collet chuck, passage Ø 160 mm

Tailstock for workpiece support

2-Axis CNC sawing unit, saw blade Ø 490 mm | 16 kW

Transfer slide with horizontal CNC rotary table and clamping station

3-Axis workpiece gripper for workpiece removal

Removal system for workpieces and remnants

Application range of High-Production-Line

Materials from high-strength steel to plastics

Elongated workpieces with multi-sided machining

Profiles of different dimensions

Shafts, tubes, traverses and the like

Single part or small batch production from solid material

Technical Information

Swivel head

Swivel angle: ± 105° infinitely variable

Positioning accuracy: ± 3"

Tool magazine

Tool Ø: max. 200 mm

Tool length: max. 340 mm

Main spindle drive

Torque: max. 230 Nm

Catalogs

No catalogs are available for this product.

See all of matec Maschinenbau‘s catalogsRelated Searches

- CNC machining center

- Vertical CNC machining center

- 3-axis CNC machining center

- Precision CNC machining center

- CNC milling machine

- 5-axis CNC machining center

- Vertical CNC milling machine

- High-precision CNC machining center

- Rigid CNC machining center

- High-performance CNC machining center

- Gantry CNC machining center

- High-rigidity CNC machining center

- Milling CNC machining center

- Column type CNC machining center

- Cutting CNC machining center

- Precision CNC milling machine

- CNC machining center with pallet changer

- Compact CNC machining center

- 24 tools CNC machining center

- Direct-drive CNC machining center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.