- Industrial machines and equipment

- Furnace and Heat Treatments

- Cabinet oven

- Materials Research Furnaces

Chamber furnace cabinetfor mechanical testssintering

Add to favorites

Compare this product

Characteristics

- Configuration

- chamber, cabinet

- Function

- for mechanical tests, sintering, annealing, heat treatment

- Heat source

- electric

- Atmosphere

- vacuum

- Other characteristics

- for the ceramics industry, for metallurgy, for precious metals, for non-ferrous metals, for carbon fiber, for materials testing machines

- Maximum temperature

Min.: 0 °C

(32 °F)Max.: 2,600 °C

(4,712 °F)

Description

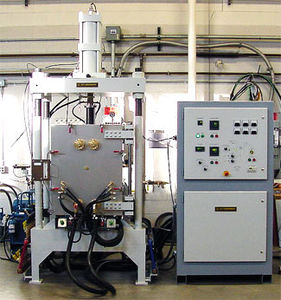

Our 5 and 10 Ton Hot Press Furnaces have a 4″ diameter x 8″ high hot zone and can be equipped with a ceramic hot zone for operation in air (1650°C max.), or a graphite or metallic zone for operation in vacuum or inert gas. Maximum temperatures are 2300°C with press rods, 2600°C in batch mode.

The press rods have 4″ of stroke with 0.001″ accuracy, and pressures up to 10 tons are controlled within 0.01% of accuracy. Available pumping systems are diffusion pumping systems, turbo pumping systems or our basic roughing vacuum systems. For temperatures above 2000°C, a thermocouple retractor and pyrometer with automatic switch-over is supplied for smooth temperature control across the operating range.

The hydraulic frame is used for both our 5 Ton and 10 Ton Hot Press Furnace but with different hydraulic components. The furnace can be equipped with classic instruments and controls, or is also available with an intuitive and easy-to-use computer interface, allowing full control of the furnace while adding user security, data trending and logging, alarming, recipe management, networking, etc. The furnace can easily be converted to a batch furnace for production.

Catalogs

No catalogs are available for this product.

See all of Materials Research Furnaces‘s catalogsOther Materials Research Furnaces products

HOT PRESSING FURNACES

Related Searches

- Furnace

- Chamber furnace

- Electric furnace

- Heat treatment furnace

- Laboratory furnace

- Combustion furnace

- Gas furnace

- Stainless steel furnace

- Tunnel furnace

- Baking oven

- Industrial furnace

- High-temperature furnace

- Controlled atmosphere furnace

- Vacuum furnace

- Continuous furnace

- Annealing furnace

- Forced convection furnace

- Programmable furnace

- Melting furnace

- Air circulating furnace

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.