- Industrial machines and equipment

- Furnace and Heat Treatments

- Chamber oven

- Materials Research Furnaces

Chamber furnace B-14electricgasvacuum

Add to favorites

Compare this product

Characteristics

- Configuration

- chamber

- Heat source

- electric, gas

- Atmosphere

- vacuum, inert gas

- Other characteristics

- custom, graphite

- Maximum temperature

Max.: 3,000 °C

(5,432 °F)Min.: 0 °C

(32 °F)

Description

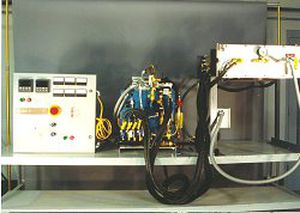

B-14 Bottom Loading Furnace

Our B-14 bottom loading furnace has a heating area of 14” dia. X 22” high (356mm dia. X 559mm high) and has almost five times the heated volume of our B-8 model making this model well suited for large volume or high capacity work loads in production environments. With specifications similar to our smaller units such as heating temperatures up to 3000°C for select materials, vacuum systems and gas systems for oxidizing, reducing and inert evironments, and numerous options, this furnace can be configured to specific process needs.

Recommended for production furnaces, we provide user friendly HMI software with fully automated custom run profiles integrating loading, atmosphere preparation, heating, cooling and unloading variables in one recipe. Run data is collected, stored, and is available for reporting and quality control locally or over the enterprise network.

General Specifications:

Hot zone size: 14” dia. X 22” high (356mm dia. X 559mm high)

Materials & maximum temperatures:

Ceramic, 1700°C max.

Molybdenum, 1650°C max.

Tungsten, 3000°C max.

Graphite, 3000°C max.

+/- 10°C temperature gradient across zone

Electric lift for loading and unloading

Includes rough vacuum and inert gas system

Available with high vacuum systems, flammable gas systems and other options

Catalogs

Product Catalog

112 Pages

Other Materials Research Furnaces products

Other Furnace Categories

Related Searches

- Furnace

- Chamber furnace

- Electric furnace

- Heat treatment furnace

- Laboratory furnace

- Combustion furnace

- Gas furnace

- Stainless steel furnace

- Tunnel furnace

- Baking oven

- Industrial furnace

- Controlled atmosphere furnace

- High-temperature furnace

- Vacuum furnace

- Annealing furnace

- Continuous furnace

- Forced convection furnace

- Programmable furnace

- Melting furnace

- Thermal furnace

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.