- Production Machines

- Other Manufacturing Equipment

- Paper folding machine

- Mathias Bäuerle GmbH

Paper folding machine prestigeFOLD NET 38electricautomatic

Add to favorites

Compare this product

Characteristics

- Material

- for paper

- Operation

- electric, automatic

- Folding length

3.5 cm

(1.4 in)

Description

Starting with the unfolded sheet size, the chosen type of fold and the paper thickness measured by the paper thickness sensor, the computer control calculates the positions of the various setting elements and adjusts them accordingly.

Intelligent machine control and touch screen operation simplify the folding process. The central touch screen panel is the interactive operator interface where all important settings are made. Manual interference is reduced to a minimum. The operator guidance is self-explanatory. The operator knows at any time which menu is active and which options are still available. Through an interface prestigeFOLD allows integration into in-plant networks. This is the basis for transfer of data to the machine by means of a JDF-file or for production data acquisition.

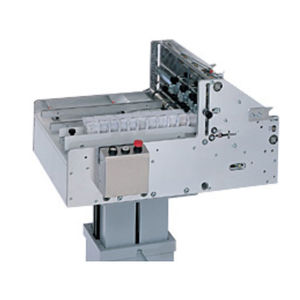

Feeders

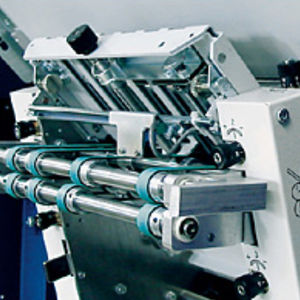

Fold plates

Deflectors

Alignment rails

Fold rollers

Deliveries

max. paper size -

38 x 65 cm (PBA)

38 x 75 cm (FSA)

min. min size -

7 x 12 cm (PBA)

10 x 12 cm (FSA)

min. fold length -

3.5 cm

(1.8 cm with KF 31)

Speed - max. 220 m/min

max. paper size - 52 x 85 cm

min. paper size - 10 x 12 cm

min. fold length - 3.5 cm (1.8 cm with KF 31)

stack height of feeder - 66 cm

20 folds are pre-programmed

Other folds are freely programmable

Program memory for 200 repetitive jobs

Fold units with 4 or 6 fold plates

Expandable up to 3 buckle fold units

Can be combined with mobile knife fold unit

VIDEO

Catalogs

prestigeFOLD NET 38

2 Pages

prestigeFOLD NET 52

2 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.