Vibration test stand VTSautomatedmanualcomputer-controlled

Add to favorites

Compare this product

Characteristics

- Test type

- vibration

- Operating mode

- automated, manual, computer-controlled, PLC-controlled

- Test material

- for engine components

- Sector

- for the aeronautical industry

Description

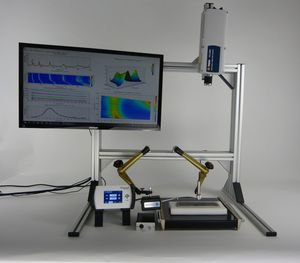

These test stands are developed for high resolution determining of blade resonances. Especially the influence of the clamping of the blades was minimized to guarantee high repeatability.

Advantages & Innovation

Automated test system for determining natural frequencies and damping

Test procedure according to company internal standards

Cost and time savings due to low personnel costs

Scalable for different blade types and sizes

Software-controlled component clamping using hydraulics

Different clamping blocks depending on blade size

Excitation by automatic modal hammer

One click reporting

Blade database

Easy to use

Export to Excel, ASCII or SAP

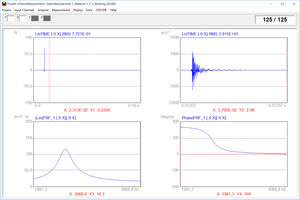

Vibration measurement with Laser Doppler Vibrometer, accelerometer or microphone

Frequency range up to 100 kHz

Frequency resolution < 1Hz at 20 kHz

Project-oriented database structure

SQL database for multiple workstations

Vibration measurement with Laser Doppler Vibrometer, accelerometer or microphone

Applications & Integrations

Component tests for gas and steam turbines

Component testing of aircraft engines

Turbine blades, compressor blades

Compound material components

blade refurbishment

Quality Control

Series testing

Research and Development

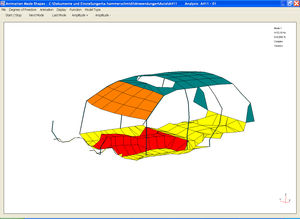

Model updating

Experimental modal analysis

Catalogs

VTS

3 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.