- Production Machines

- Plastics Processing

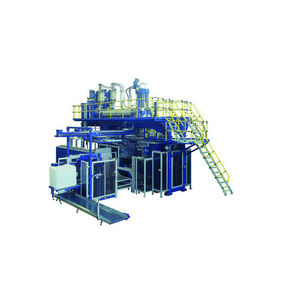

- Extrusion blow molding machine

- Mauser Packaging solutions

Extrusion blow molding machine BM 202multilayerautomatictwin-station

Add to favorites

Compare this product

Characteristics

- Type

- extrusion

- Other characteristics

- multilayer, automatic, twin-station

- Hollow part volume

Min.: 60 l

(15.9 gal)Max.: 250 l

(66 gal)- Clamping force

750 kN

Description

The MAUSER BM 202 blow molding machine is mainly used for the production of big size plastics packaging such like the MAUSER L-Ring and Open Top drums. According to the market requirements this machine can be customized by optional systems accessories, like fully automated deflashing, weighing, leaktesting, etc..

Machine characteristics:

- Double-station high performance extrusion blow molding machine

- Multi-layer technology up to 4 layers available

- For packaging from 60 to 250 liter capacity

- Outperforming extrusion capabilities

- State-of-the-Art technology

- Process optimization

- Computer supported control systems

Customer benefits:

- High productivity up to 100 pieces per hour (220 l OT drum)

- Increased performance, especially with aftercooling equipment

- Fully automatic in-line production possible

- Top product quality through outstanding extrusion technology

- "State-of-the-art" security systems for safe operation

- Easy operation and maintenance by self-explaining control system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.