- Production Machines

- Plastics Processing

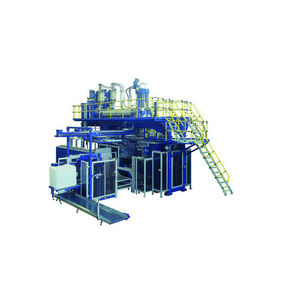

- Extrusion blow molding machine

- Mauser Packaging solutions

Extrusion blow molding machine SBM 21automatic

Add to favorites

Compare this product

Characteristics

- Type

- extrusion

- Other characteristics

- automatic

- Hollow part volume

Min.: 20 l

(5.3 gal)Max.: 30 l

(7.9 gal)- Clamping force

300 kN

Description

The new high performance SBM 21 blow molding machine is used for the production of 20 – 30 l industrial jerrycans, especially for plastics packaging designed for the transport of dangerous filling goods.

The SBM 21 blow molding machine is manufactured by MAUSER and SABMANN BLASFORMTECHNIK in Thailand.

Machine characteristics:

- Single station blow molding machine

- Production of jerrycans from 20 – 30 l volume

- State-of-the-art technology

- Continuous extrusion (view stripe option)

- WDS / SDDR wall thickness control as standard (PWDS option)

- Hydraulic or electric version

- Bottom blow

- Integrated after cooling and deflashing

- Compact design

Customer benefits:

- High productivity and reliability

- Top product quality through outstanding extrusion technology

- HMW-HDPE as pellets or powder material processable

- Easy to use control system (PC based control technology)

- Easy maintenance

- Long life design

- Fully automatic in-line production possible (i.e. automatic weighing, leaktesting, packing systems, etc.)

- Worldwide service by MAUSER / SABMANN specialists

Catalogs

No catalogs are available for this product.

See all of Mauser Packaging solutions‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.