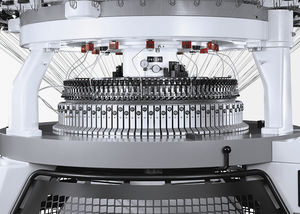

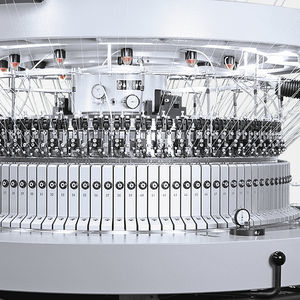

Circular knitting machine D4-2.2 X double jerseyindustrial

Add to favorites

Compare this product

Characteristics

- Type

- circular, double jersey

- Domain

- industrial

- Working width

Max.: 2,750 mm

(108 in)Min.: 1,905 mm

(75 in)

Description

Flexible to the finest detail

With its 2.2 feeders per inch the D4 2.2 X achieves a very high level of productivity for fine rib and many other rib structures. Fine gauge up to E40 is also part of the D4 2.2 X’s repertoire. The machine’s 3-hole ceramic yarn guide is wear-free and contributes to its high flexibility. The D4 2.2 X also offers elastomeric plating.

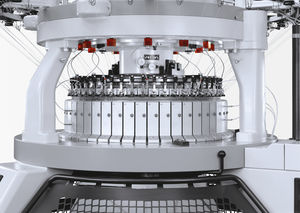

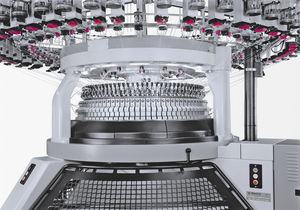

The HPI version: From rib to interlock

In the HPI version the D4-2.2 II is a mass producer of smooth interlock fabrics. This version comes with 4.4 feeders per inch. At 30 inches that is 132 feeders at an impressive 34 rpm – a level of productivity unequalled anywhere in the world. The D4 2.2 HPI processes both filament and fibre yarns in interlock production. The central stitch adjustment makes it child’s play to use.

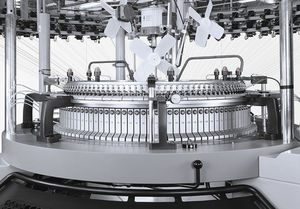

Spacer fabric with a wide range of choices

On the D4 2.2 X, spacer fabric can be knitted with the finest gauges and either with all of the needles or with a 1:1 selection of needles. The machine also offers elastomer plating options. The elastomeric yarn can be platted both in the cylinder and in the dial tube. The D4 2.2 X also has an optimised yarn supply that helps to prevent fluctuations in tension during delivery.

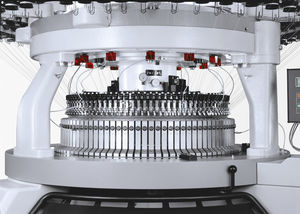

A wide range of fabric widths in all 8-lock structures

The D4 2.2 X is available in open width, industry and giant frames of up to 48 inches. Depending on the frame, fabric rolls with a diameter of 520 mm, 920 mm and 1,250 mm can be manufactured. Fabric rolls rolled on an open width frame have diameters of 280 mm, 330 mm and 600 mm. Fabric widths range from 1,905 mm to 2,750 mm.

Catalogs

D4-2.2 X

4 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.