- Industrial machines and equipment

- Surface Treatment Equipment

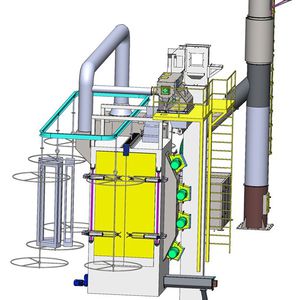

- Roller conveyor shot blasting machine

- MAYFLAY Machinery (Huizhou) Co., Ltd.

Roller conveyor shot blasting machine MTR seriesfor metalsheet metalautomatic

Add to favorites

Compare this product

Characteristics

- Type

- roller conveyor

- Applications

- for metal, sheet metal

- Other characteristics

- automatic, continuous, compact, turbine, multipurpose

Description

Roller Conveyor shot blasting machine

Roller conveyor shot blasting machine is built to clean steel plates and profiles. They are mostly used for descaling, derusting, paint removal, paint preparation, deburring and general surface preparation prior welding, cutting, machining and burning operations.

Brief Profile

Roller conveyor shot blasting machines, specially designed for constant and continuous blasting of de-scaling, de-sanding, cleaning and pre-treatment for different type of steel, like steel plates, steel girder, shape steel, structural steel, steel pipe, steel castings etc. It is usually long and giant but compact, configurable with 4-16 sets of blast wheels and even more to meet different requirements of surface cleaning and strengthening.

The transport system is the rollers conveyor, driven steadily and stably by the chain and chain wheel and loaded with rollers of 80mm, 121mm, 180mm in diameter or even bigger, can load work pieces from 500KG to 2000KG and even heavier. Work pieces are loaded on the inlet of roller conveyor, being blasted in the blasting chamber, and come out from the outlet roller conveyor for unloading. continuous blasting process with one press of the button.

Load, roller transport, blast, unload. This is a through-type and continuous production line with high efficiency and an ideal option for surface cleaning of long and large steel materials, structural steel, steel welding part etc.

VIDEO

Catalogs

No catalogs are available for this product.

See all of MAYFLAY Machinery (Huizhou) Co., Ltd.‘s catalogsOther MAYFLAY Machinery (Huizhou) Co., Ltd. products

SURFACE TREATMENT EQUIPMENT

Related Searches

- Blast machine

- Metal shot blasting machine

- Blast room

- Automatic blast machine

- Hand blast cabinet

- Pressure blast room

- Continuous shot blasting machine

- Belt shot blasting machine

- Turbine shot blasting machine

- Hook shot blasting machine

- Injector blast cabinet

- Roller conveyor blast machine

- Rotating table shot blasting machine

- Compact blast machine

- Blast cabinet with turntable

- Multipurpose shot blasting machine

- Pipe shot blasting machine

- Sheet metal shot blasting machine

- Shot peening machine

- Metal shot peening machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.