- Industrial machines and equipment

- Surface Treatment Equipment

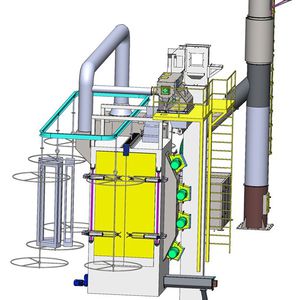

- Suction blast cabinet

- MAYFLAY Machinery (Huizhou) Co., Ltd.

Suction blast cabinet MS seriesmanualwith turntable

Add to favorites

Compare this product

Characteristics

- Technology

- suction

- Operational mode

- manual

- Other characteristics

- with turntable

- Width

500 mm, 600 mm, 900 mm, 1,500 mm

(19.7 in, 23.6 in, 35.4 in, 59.1 in)- Height

500 mm, 600 mm, 700 mm, 1,400 mm

(19.7 in, 23.6 in, 27.6 in, 55.1 in)

Description

Sandblasting Cabinet

Sandblasting Cabinet is a kind of machine that uses compressed air as power to form a high-speed jet beam which sprays the abrasives into the surface of the workpiece to be treated at high speed. Because of the impact and cutting action of abrasives on the workpiece surface, the workpiece surface is cleaned up to a certain extent and has different roughness, so the mechanical properties and fatigue resistance of the workpiece surface are improved, and the adhesion between the workpiece and the coating is increased, the durability of the coating is prolonged, and it is also conducive to the leveling and decoration of the coating.

Brief Profile

Siphonic-type manual sandblasting machine, high-pressure manual sandblasting machine and automatic turntable sandblasting machine are Mayflay’s main types of sandblasting machine. They differentiate from each other with different ways of blasting to adapt to various missions of sand blasting.

In siphonic-type manual sandblasting, compressed air is feeding power and accelerating power for sand stream, working in the way that sands are sucked into the sand-blasting gun through the sand hose by the negative pressure in the sand-blasting gun by high-speed compressed air and blast on work piece’s surface to have expected treatment result.

In high-pressure manual sandblasting, compressed air is the blasting power, sands are accelerated and pushed by the highly compressed air from the pressure tank out of the blasting gun through the sand hose to blast on work piece’s surface to have expected treatment result.

Catalogs

No catalogs are available for this product.

See all of MAYFLAY Machinery (Huizhou) Co., Ltd.‘s catalogsOther MAYFLAY Machinery (Huizhou) Co., Ltd. products

SURFACE TREATMENT EQUIPMENT

Related Searches

- Blast machine

- Metal shot blasting machine

- Blast room

- Automatic blast machine

- Hand blast cabinet

- Pressure blast room

- Continuous shot blasting machine

- Belt blast machine

- Turbine shot blasting machine

- Hook shot blasting machine

- Injector blast cabinet

- Roller conveyor blast machine

- Rotating table shot blasting machine

- Compact blast machine

- Blast cabinet with turntable

- Multipurpose shot blasting machine

- Pipe shot blasting machine

- Sheet metal shot blasting machine

- Shot peening machine

- Metal shot peening machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.