- Packing - Handling - Logistics

- Conveying

- Press feeding line for the automotive industry

- MAYFLAY Machinery (Huizhou) Co., Ltd.

Fine blanking coil feeding line MFL4 seriesfor the automotive industryfor high-strength steelcompact

Add to favorites

Compare this product

Characteristics

- Applications

- for fine blanking, for the automotive industry, for high-strength steel

- Other characteristics

- compact

Description

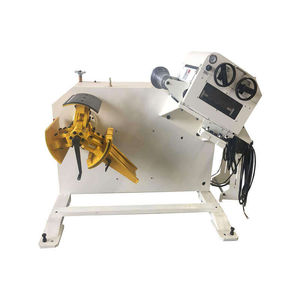

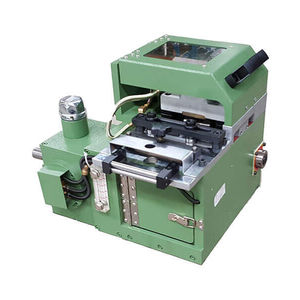

High Strength Compact Coil Feeding Line

Applicable Material

Raw Material Type: High Strength Steel steel, Hot-Rolled Metal steel, Cold-Rolled Metal steel, Galvanized Metal steel ,Stainless Steel etc.

Coil Width: 100-1800 mm

Material Thickness: 0.6-6.0 mm

Yield Strength: ≤613 N/mm2

Tensile Strength: ≤980 N/mm2

Brief Profile

Coil Feeding Lines with compact design are preferred to be used in case of only small available space as well as in case of less delicate coil material with big material square. They normally are used at middle-sized feeding lengths and middle-sized number of press strokes per minute.

Compact Feed Line for high strength material is designed to make the thick steels with higher tensile strength above 400Mpa. They offer process reliability even for the most demanding materials. They are optimally suited for the manufacture of structural parts as well as for processing of high-strength materials,even for the higher ranges of strip thickness.With our Compact coil systems you can process coil material width from 400mm to 1800mm, coil thickness from 0.6-9.0mm, coil weight up to 25000kgs.

Compact Coil feed line is a metal forming process widely used to produce parts for various industries, such as automotive stamping, electronics stamping and appliances stamping and etc.

VIDEO

Catalogs

Other MAYFLAY Machinery (Huizhou) Co., Ltd. products

COIL HANDLING EQUIPMENT

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.