- Production Machines

- Cutting Machine

- Mechanical press

- MAYFLAY Machinery (Huizhou) Co., Ltd.

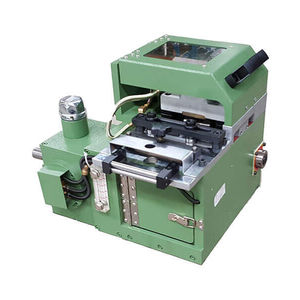

Mechanical press APA seriesstampingbendingpunching

Add to favorites

Compare this product

Characteristics

- Operation

- mechanical

- Function

- stamping, bending, punching, blanking, embossing

- Force

Max.: 110 tf

Min.: 15 tf

Description

High Precision Press Machine

Stamping includes a variety of sheet-metal forming manufacturing processes, such as punching using a machine press or stamping press, blanking, embossing, bending, flanging, and coining. This could be a single stage operation where every stroke of the press produce the desired form on the sheet metal part, or could occur through a series of stages. The process is usually carried out on sheet metal.

Metal sheet press feed line is a metal forming process widely used to produce parts for various industries, such as automotive stamping, electronics stamping and appliances stamping and etc.

Brief Profile

Mechanical Power Press Machine drives the flywheel by motor, drives the crankshaft connecting rod mechanism by clutch and transmission gear to move the slider up and down, and drives the tensile mold to shape the steel plate.And the power press has two sliders, divided into sliding block inside and outside the slider, within the slider drive mould punch or die, outside the pressure of the slider to drive mould to coil, pressure rim first action during tensile steel edge, inner sliding block action stretch again.

Mechanical Power Press Machine is used for blanking, punching, bending and forming of small and medium-sized single-engined thin steel plates and high-speed progressive die parts. It is characterized by high-precision, high-yield and high-stability continuous stamping operations.

With high rigidity design in machine frame, high precision power press body is welded of quality steel sheet and treated by tension elimination, improve stability and reliability of precison of the machine.

Catalogs

No catalogs are available for this product.

See all of MAYFLAY Machinery (Huizhou) Co., Ltd.‘s catalogsOther MAYFLAY Machinery (Huizhou) Co., Ltd. products

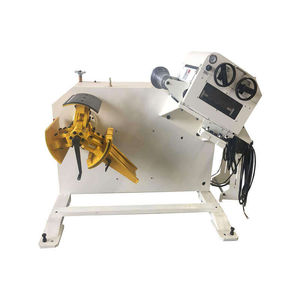

COIL HANDLING EQUIPMENT

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.