- Production Machines

- Forming Machine

- Stamping press

- MAYFLAY Machinery (Huizhou) Co., Ltd.

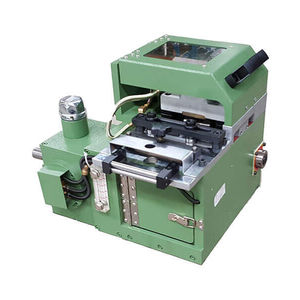

Stamping press C seriesC-framehigh-speed

Add to favorites

Compare this product

Characteristics

- Function

- stamping

- Structure

- C-frame

- Other characteristics

- high-speed

- Force

25 tf, 45 tf, 65 tf, 85 tf

Description

C Frame High Speed Press Machine

Material Type: Stainless Steel, Copper, Aluminum etc.

Yield Strength: ≤245 N/mm2

Tensile Strength: ≤392 N/mm2

Material Thickness: 0.1-1.0 mm

Coil Width: 20-200mm

Speed: 200-1000SPM

Suitable for metal button and eyelet stamping line

Brief Profile

C frame high speed press machine use integrated special cast iron alloys with high rigidity and shock resistance. The slider is designed with a long guide and equipped with a slider balancing device to ensure precise and stable operation. All anti-wear components are electronically timed automatic lubrication systems, such as the lack of lubricant, the punch will be fully automatic stop. Advanced and simple control system ensures the accuracy of the running and stopping of the slider. It can be used with any automated production requirements to increase production efficiency and reduce costs.

The design principle of the high speed press is to convert the circular motion to linear motion. The main motor is used to drive the flywheel and the clutch drives the gear, crankshaft (or eccentric gear), connecting rod, etc. To achieve the linear movement of the slider from the main motor to the movement of the connecting rod is a circular motion. There must be circular and linear movement between the connecting rod and the slider. There are roughly two types of mechanism in the design, one is a ball type, and the other is a pin type (cylindrical type). Through this mechanism, the circular motion Converts the linear motion of the slider.

Catalogs

No catalogs are available for this product.

See all of MAYFLAY Machinery (Huizhou) Co., Ltd.‘s catalogsOther MAYFLAY Machinery (Huizhou) Co., Ltd. products

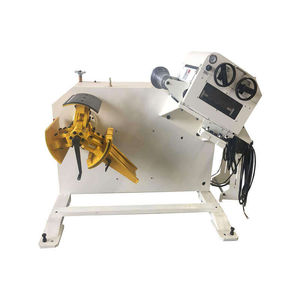

COIL HANDLING EQUIPMENT

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.