• Precision sheet coating machine made from high precision, certified industrial components

• Granite base for rigidity and vibration damping

• Vacuum chuck flatness better than 5 µm with sheet feeding system

• Custom width slot-die coating heads up to 650 mm width

• Motorized, programmable height gap adjustment with a resolution of 1 µm

• Motorized, programmable coating offset adjustment with a resolution of 1 µm

• Motorized vacuum chuck movement with linear servo and drive amplifier

• Synchronised material syringe pump – (Option: multiple syringe pumps may be controlled simultaneously)

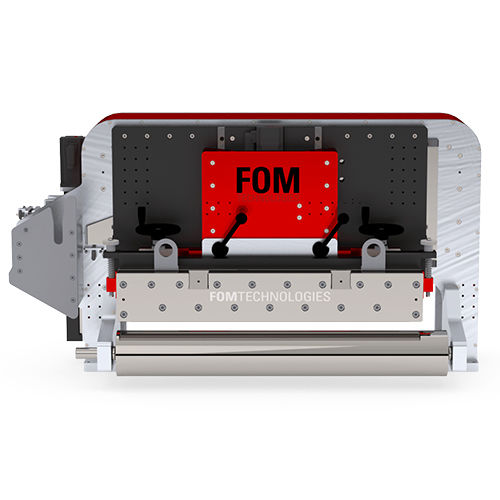

High precision automated S2S coating system

The FOM pontumSC provides an automated slot-die sheet coating system for high-end applications requiring high precision control of coating in repeated sheetfed steps.

Fully integrated system control

The FOM pontumSC comes with a fully integrated system control of the slot-die head, pumps, and substrate stage movement. XY-stages allow for precise slot-die head and substrate positioning, while the Z-stage is optimized for ultra-smooth coating motion. An inline sheet feeding system allows for multiple consecutive coatings.

Easy repetition and use of recipes

The system facilitates the easy execution of repeated precision coatings in a controllable, easily predictable manner, giving a high yield in each production run.