- Machine-tools

- Machining Center

- 4-axis machining center

- MCM Machining Centers Manufacturing

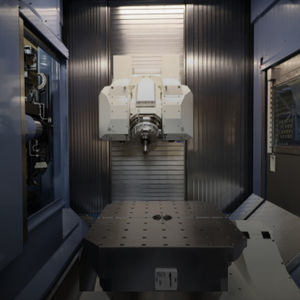

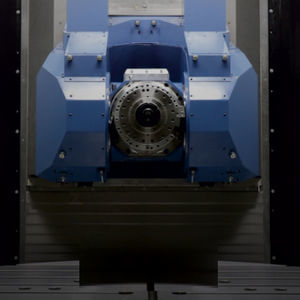

5-axis machining center CLOCK 1200 EVO4-axisverticalwith rotary tilting table

Add to favorites

Compare this product

Characteristics

- Number of axes

- 5-axis, 4-axis

- Spindle orientation

- vertical

- Structure

- with rotary tilting table

- Associated functions

- milling

- X travel

1,200 mm

(47.24 in)- Y travel

1,000 mm

(39.37 in)- Z travel

1,000 mm, 1,100 mm

(39.37 in, 43.31 in)- Rotational speed

Min.: 8,000 rpm

(50,265 rad.min-1)Max.: 30,000 rpm

(188,496 rad.min-1)- Work feed X-axis

75,000 mm/min

(49 in/s)- Work feed Y-axis

75,000 mm/min

(49 in/s)

Description

All MCM machining centres are designed to ensure uncompromising maximum performance in terms of contents and construction quality. High productivity, stiffness, precision, reliability and excellent dynamics are key features throughout the range.

All families are designed to provide a wide range of configuration options, mainly in terms of axes stroke, machine layouts, technical features, accessories and process control devices.

In the most complex cases, the widespread know-how and the flexible organization make possible even extreme product customisations. All machines are available in 4-axis and 5-axis versions and can also be configured for multitasking operations, such as milling, turning, grinding, boring, etc.

The high levels of automation are achieved through the MCM systems for handling of workpieces, pallets, tools, which are an integral part of the range. All machining centres can be configured with a single pallet, pallet exchanger, multi-pallet systems or integrated in FMS. The level of automation can be changed or increased during the service life of the plant, providing considerable flexibility.

The machines can be equipped with a supervision system, developed exclusively by MCM, which integrates and amplifies the potential of normal NCs, with absolute benefits in terms of production flexibility, process reliability and efficiency, monitoring of current machine conditions, scheduled and predictive maintenance.

VIDEO

Catalogs

No catalogs are available for this product.

See all of MCM Machining Centers Manufacturing‘s catalogsOther MCM Machining Centers Manufacturing products

MACHINING CENTERS

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.