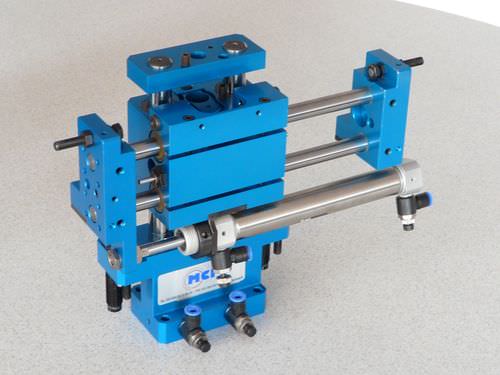

Transport manipulator combined motionlinear array

Add to favorites

Compare this product

Characteristics

- Applications

- transport

- Other characteristics

- combined motion, linear array

Description

The linear transport arms work on both vertical and horizontal planes and with the same precision in compact and narrow units. There is just a slight difference in the technicality of operation. The vertical movement is created by the means of a double acting piston that is located at the unit base. Horizontal movements are produced by a standard piston. Such design reduces the number of moving parts. The horizontal and vertical movements are on ball-bearing guide bushes. End jarring is going to be eliminated by self-adjusting shock absorbers. Flow rate controllers mounted directly on the arm adjust the advance, up and down speeds. Linear arms are 2 separate low-operating positions for picking up and setting down components in tight working spaces.

Catalogs

No catalogs are available for this product.

See all of MCPI SAS‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.