Feedback Control Technology:

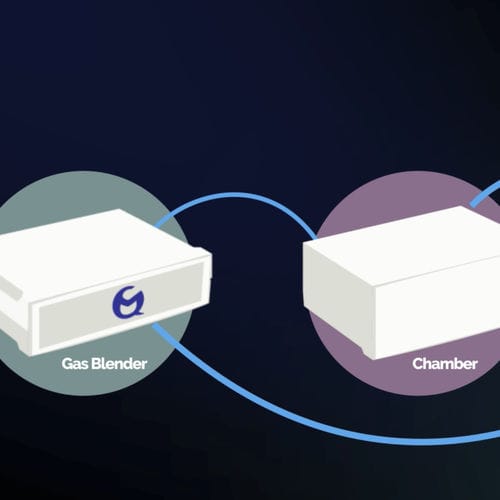

Thanks to our Feedback Control Technology, you will be able now to modify the percentages of single components of a gas mixture which flows inside a chamber/bioreactor/incubator, with a feedback in a closed loop control, in an automated way.

CASE 1

Gas mixer + Bioreactor + Analyzer

This is the case in where our Gas Mixer injects the gas mixture inside a Bioreactor. Then the Analyzer can read the result and our instrument is now able to check if the result is optimal, so it means anything changes.

But if any parameter varies in a negative condition for your needs, a signal is sent with a Digital Feedback Control to the Gas Mixer which adapts itself changing the percentages of the components of the gas mixture in an absolutely automated way.

CASE 2

Gas mixer + Bioreactor/Sensor + Analyzer

This is the case in where we create a system which allows to constantly monitor a whole process that otherwise would be brought forward using an obsolete BATCH SYSTEM.

OLD SOLUTION: The Gas Mixer injects a gas mixture inside a Bioreactor, that will be then detached and closed for the proper time that the reaction needs. It will be NOT possible to monitor the process during the required time. With the consequence that the result of the reaction can reserve too many unexpected surprises after several days.

THE MCQ INSTRUMENTS SOLUTION: Inserting a Sensor inside the Bioreactor, we are now able to constantly monitor the whole process and, if it is degenerating towards unacceptable parameters, we can adjust the gas mixture and restoring the correct atmosphere, in a full AUTOMATION.

Ask us for more info