- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

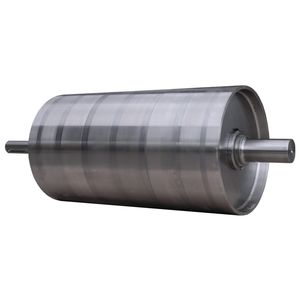

Magnetic grate separator RRM seriesmetalfor the food industryautomatic

Add to favorites

Compare this product

Characteristics

- Technology

- magnetic grate

- Separated substance

- metal

- Application domain

- for the food industry

- Other characteristics

- automatic, stainless steel, rotary

Description

Ensures the highest possible llevel of ferromagnetic particles separation and consequently higher quality of finished products.

Efficient operation. Without stopping the material and interrupting operatons.

Without stopping material and interrupting work.

Stainless steel casing.

Control unit: the latest digital technology, digital and analogue filters, automatic balancing.

Remove metal contaminants and avoid damage to the molding-injection devices, thrust systems, cylinders, mixing machines, presses and other equipment. The metal contaminants thus pose a problem, due to which the quality of the products reduces or the manufacturing process stops.

The RRM rotating magnetic grates and MFC conduit magnetic filters ensure a separation of metallic contaminants. This is very important in the manufacturing of plastics.

Rotating magnetic grates are particularly suitable for the application in the food industry, namely for products such as sugar, flour, powdered milk and similar.

VIDEO

Catalogs

No catalogs are available for this product.

See all of MDR d.o.o.‘s catalogsRelated Searches

- Solid classifier

- Eddy current separator

- Process classifier

- Gravity classifier

- Classifier for the recycling industry

- Particle classifier

- Classifier for the food industry

- Ferrous metal separator

- Automatic separator

- Separator for the chemical industry

- Self-cleaning separator

- Compact classifier

- Metal detector for the food industry

- Stainless steel separator

- Vertical classifier

- Tunnel type metal detector

- Bulk material separator

- Conveyor metal detector

- Magnetic drum separator

- Metal detector with conveyor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.