- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

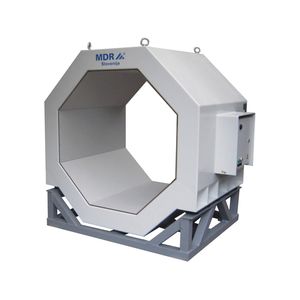

Tunnel type metal detector TKDE Zfor conveyormagneticfor the food industry

Add to favorites

Compare this product

Characteristics

- Type

- tunnel type

- Applications

- for conveyor

- Other characteristics

- magnetic

- Domain

- for the food industry, for the textile industry, for the wood industry

Description

Easy installation in manufacturing lines.

Automatic separation of the product contaminated with metal - with separation mechanism on conveyor system.

Application: possible as a system solution in combination with a conveyor system and automated separation mechanism.

Customization to the customer’s needs.

Construction in accordance with the HACCP and IFFAS recommendations.

The highest performance in detecting magnetic and non-magnetic metals.

Accurate manual or automatic product compensation (self-learning).

Fast and safe ejection of the contaminated product.

Minimum number of false detections (due to analogue and digital filters).

By using the RS232 or RS485 communication or ethranet you can track detections, print reports and modify the basic parameters through the remote access via personal computer.

Many years of stable operation (automatic calibration).

More important parameters of a detector are protected by a password.

The possibility to enter 30 different settings for products.

Clear and simple-to use multi-level menus.

Simple assembly, disassembly and cleaning.

Casing from high quality stainless steel.

Possibility of integrated or separate electrical equipment.

Simple replacement of the power supply or processing module in case of malfunction.

Catalogs

Related Searches

- Solid classifier

- Eddy current separator

- Process classifier

- Gravity classifier

- Classifier for the recycling industry

- Particle classifier

- Classifier for the food industry

- Ferrous metal separator

- Automatic separator

- Separator for the chemical industry

- Self-cleaning separator

- Compact classifier

- Metal detector for the food industry

- Stainless steel separator

- Vertical classifier

- Tunnel type metal detector

- Bulk material separator

- Conveyor metal detector

- Magnetic drum separator

- Metal detector with conveyor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.