- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

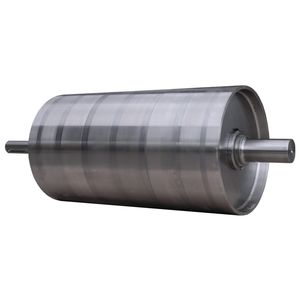

Magnetic drum separator MB-SZfor bulk materialsprocessraw materials

Add to favorites

Compare this product

Characteristics

- Technology

- magnetic drum

- Separated substance

- for bulk materials

- Application domain

- process

- Other characteristics

- automatic, stainless steel, raw materials

Description

The magnetic drum/separator is intended for automatic cleaning of mixtures containing larger amounts of iron and iron oxides, which we want to separate from the raw material/ore itself.

Due to the very difficult working conditions, the entire magnetic drum is made of stainless steel and is additionally protected with polyurethane due to the high abrasion of the material. The auger is used for automatic removal of iron and iron foreign bodies. The auger is made of hardox and the excretory auger is made of stainless steel, which is also additionally protected with polyurethane due to high abrasion.

A magnetic drum/separator is used to clean the ore (for example gold), which also contains impurities of iron oxides and iron. The ore, mixed with sand and water, travels to a concentrator where the ore is separated from the sand and soil. When using the centrifugal force of the concentrator, sand and water are easily separated from ore (gold). However, since iron and gold have a very specific material density compared to water and sand, it is separated together as a single mixture (ore + iron). The problem that arises is that in the process of separating ore from other premises with the help of g-force (centrifugal force) in addition to ore (gold) also eliminates large amounts of iron and iron oxides, which usually occur in the extraction of ore (gold).

Further extraction of iron and iron oxides from ore (gold) is very time consuming and also difficult, as in the extraction of iron and iron oxides there is a problem to remove not only iron and iron oxides but also many already found ores (gold). As a result, gold yields are lower and the ore mining process is longer.

VIDEO

Catalogs

No catalogs are available for this product.

See all of MDR d.o.o.‘s catalogsRelated Searches

- Solid classifier

- Eddy current separator

- Process classifier

- Gravity classifier

- Classifier for the recycling industry

- Particle classifier

- Classifier for the food industry

- Ferrous metal separator

- Automatic separator

- Separator for the chemical industry

- Self-cleaning separator

- Compact classifier

- Metal detector for the food industry

- Stainless steel separator

- Vertical classifier

- Tunnel type metal detector

- Bulk material separator

- Conveyor metal detector

- Magnetic drum separator

- Metal detector with conveyor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.