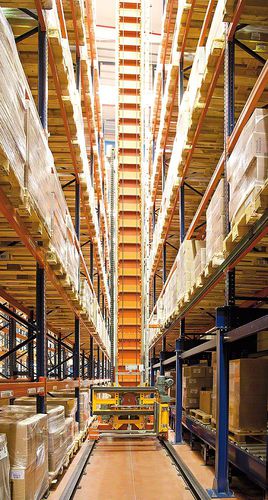

Automatic trilateral stacker crane

Inexpensive automating. Simple to implement. Reduction of errors. Improves security on the premises. Low maintenance costs.

Automated trilateral stacker crane to replace manned trilateral forklifts.

The automatic trilateral stacker crane: a fast an economical way to automate warehouses.

Advantages:

• - The perfect solution to automate conventional racks of up to 15 meters in height.

• - No need to modify the warehouse structure.

• - Trilateral extraction integrated system.

Why use an automatic trilateral stacker crane?

• - Adapts to all pallet warehouses with man-operated elevator trucks.

• - Economical automating. The investment is paid off quickly.

• - Easy to implement, both in new and pre-existing warehouses, since it doesn’t require any changes to the warehouse structure.

• - Decrease in personnel costs. It allows you to manage all the pallet movements without a man on board.

• - Using all available space since it does not have a top guide and it can pick up pallets from level 0.

• - Reduces errors since it is an automatic system.

• - Improves safety in the facility. Operators do not work in the passageways meaning the system is safer and reduces the risk of accidents occurring.

• - Low maintenance costs.

• - Easy to integrate the automatic system connecting it to a warehouse management system like Easy WMS.

Automatic trilateral stacker crane make it very easy to automate warehouses with conventional racks where a man-operated elevator truck is used, both in pre-existing warehouses and in new facilities.