- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

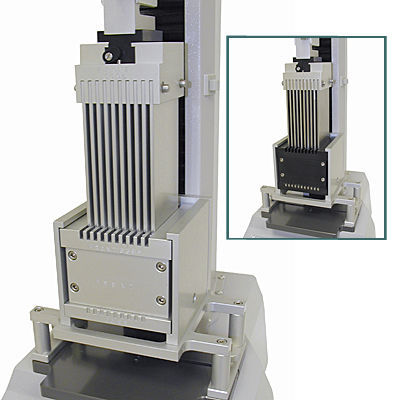

Food shear test fixture CS-1

Add to favorites

Compare this product

Characteristics

- Options

- food

Description

The main advantage of the Kramer Shear Cells (KSC), is that a large sample of the product can be tested at once. This gives a better average value of texture then testing one small piece of food multiple times and speeds texture assessment. The Kramer Shear Cell faithfully reproduces the actions of consumption by shearing, compressing and extruding the sample, measuring them together and providing increased reproducibility in a highly variable product.

One side effect from testing such an increased sample size is that higher forces are generated as a result. Since competitor systems cannot supply the higher forces, mock up designs like the “Mini Kramer/Ottawa Shear Cell” were developed to try and copy this original Allo-Kramer design. In a sense this defeats one of the big advantages derived from the ability to test larger samples.

Standard shear compression cellFTC offers two additional variations of the standard fixture, CS-1. One version is made with stainless steel blades and a Delrin cell (CS-1A) for high acid food samples, like diced tomatoes and salsa. The CS-1-TU is calibrated with fresh peas for Tenderometer use and must be "paired and calibrated" with a Model FTA-TU Force transducer before use.

Catalogs

No catalogs are available for this product.

See all of Mecmesin‘s catalogsRelated Searches

- Test machine

- Measuring device

- Test stand

- Material testing machine

- PC-controllable testing machine

- Portable testing system

- Compression test machine

- Vertical test machine

- Industrial test machine

- Universal test machine

- Digital measuring device

- Digital testing system

- Flexure testing machine

- Tensile test machine

- Laboratory test machine

- Electromechanical test machine

- Research and development test machine

- Pull testing machine

- Plastic test machine

- Moisture meter

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.