- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

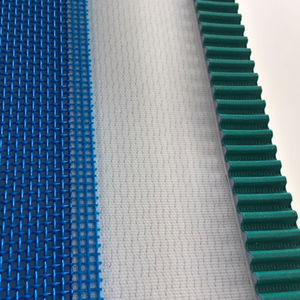

Timing belt HYBRID PRO PLUSsiliconepolyurethanethermoplastic

Add to favorites

Compare this product

Characteristics

- Type

- timing

- Material

- polyurethane, silicone, thermoplastic, PET

- Product applications

- for food, for automation, for packaging, conveyor belt

- Sector

- for the food industry, for the packaging industry, for the paper industry, medical

- Hardness

- 92 shore A

- Other characteristics

- flexible

- Width

1,000 mm

(39.37 in)- Pitch

5 mm, 8 mm, 14 mm

(0.197 in, 0.315 in, 0.551 in)

Description

The HYBRID PRO BELT PLUS is part of the HYBRID BELTS SERIES: innovative belts with unique features within the market, combining successfully the positive features of timing belts with and conveyor belts.

The main feature of HYBRID PRO BELT PLUS is the application of one, two or more QST timing belt at the edges of a polyurethane conveyor belt, in order to achieve different benefits.

Compatible for fabrication with other thermoplastic materials, many profiles and coatings are possible to suit specific applications.

Features

Driven speed up to 550 mt/min

Greater productivity

Long belt life, because the conveyor belt works without traction loads

Cost reduction - Less energy absorption (about 30%)

Energy saving

Extremely customization, covering and special reworking

Taylor made

Improved reduction in noise level

Less noisy

Mechanical and chemical properties

More compact dimension of pulleys

Less noisy

Catalogs

No catalogs are available for this product.

See all of MEGADYNE‘s catalogsRelated Searches

- MEGADYNE transmission belt

- MEGADYNE industrial belt

- MEGADYNE rubber belt

- Rigid shaft coupling

- MEGADYNE plastic belt

- Transmission shaft coupling

- MEGADYNE toothed belt

- Sleeve shaft coupling

- MEGADYNE sturdy belt

- MEGADYNE industrial belt

- MEGADYNE polyurethane belt

- MEGADYNE poly V belt

- MEGADYNE synchronous belt

- Flat strip

- Metal pulley

- MEGADYNE oil-resistant belt

- MEGADYNE elastic belt

- Toothed pulley

- MEGADYNE high-performance belt

- MEGADYNE high-resistance belt

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.