Hydraulic press MA-05laminationrollerautomatic

Add to favorites

Compare this product

Characteristics

- Operation

- hydraulic

- Function

- lamination

- Structure

- roller

- Control

- automatic

- Applications

- for battery pole

Description

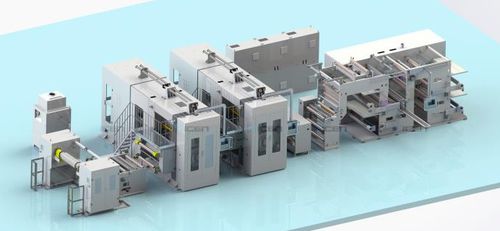

1. Using the most advanced power drive mode, two permanent magnet synchronous motors drive two hard helical gear reducers to drive two rolls through drum tooth couplings. The electronic control part mainly adopts PLC and display touch screen control, and the stable production efficiency can reach 30-100m/min.

2. Pressure method: hydraulic pressurization, cylinder down; Roll seam adjustment mode: servo motor drives the middle oblique iron automatic adjustment, left and right sides can be adjusted separately, automatic pressure compensation device, rolling force up to Max: 600T, pressure control accuracy ≤± 0.5T, hydraulic pressure displacement mode: ≤2μm.

3. Effective roll width of roll surface: 200-800mm (adjusted according to the width of the pole piece).

Catalogs

No catalogs are available for this product.

See all of MEGAROBO‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.