- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

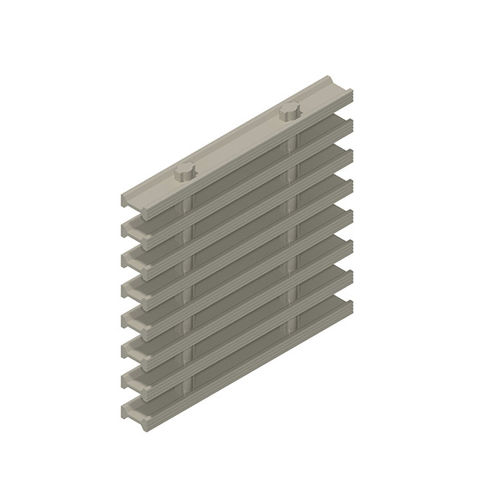

GRP grating sheet metalhigh load capacityconstruction

Add to favorites

Compare this product

Characteristics

- Material

- GRP

- Configuration

- sheet metal

- Other characteristics

- high load capacity

- Product applications

- construction, bar, profile

- Width

1,220 mm

(48 in)- Length

6,100 mm

(240.2 in)

Description

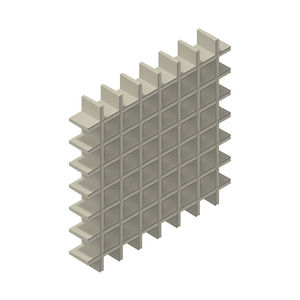

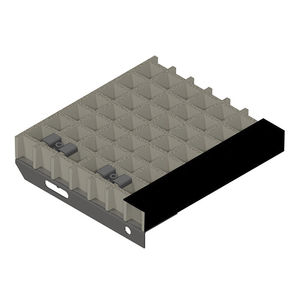

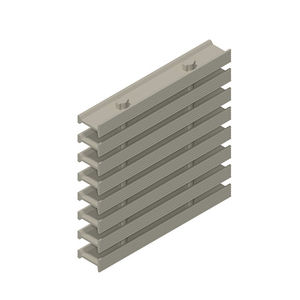

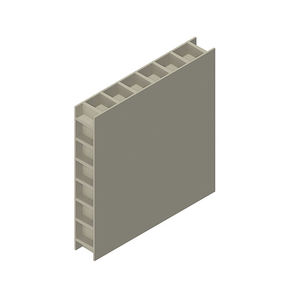

Pultruded GRP-gratings consist of bearing bars and crossbars. The percentage of glass comprises ca. 68%. Pultruded GRP gratings have a distinct higher stiffness than moulded GRP gratings. Therefore, bigger spans can be achieved or the construction height can be comparatively lowered.

The special arrangement of bearing bars and crossbars enables a permanent stability. The bearing bars are manufactured according EN 13706 with a profile layout of longitudinal glass fiber rovings, cross reinforced glass fiber mats and a surface veil.

Basically, pultruded GRP-gratings distinguish between T- or I – bar cross section. There is a range of different surfaces.

Please consider our explanations regarding anti-skid properties.

Catalogs

No catalogs are available for this product.

See all of Meiser‘s catalogsRelated Searches

- Profile

- Metal profile

- Industrial profile

- Ladder

- Rectangular profile

- Rubber matting system

- Meiser metal grating

- Grooved profile

- Meiser anti-slip mat

- Construction profile

- Meiser staircase

- Polymer profile

- Meiser metal staircase

- Meiser industrial grating

- Anodized aluminum profile

- Round profile

- Meiser non-slip grating

- Black matting system

- Meiser steel grating

- Meiser galvanised steel grating

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.