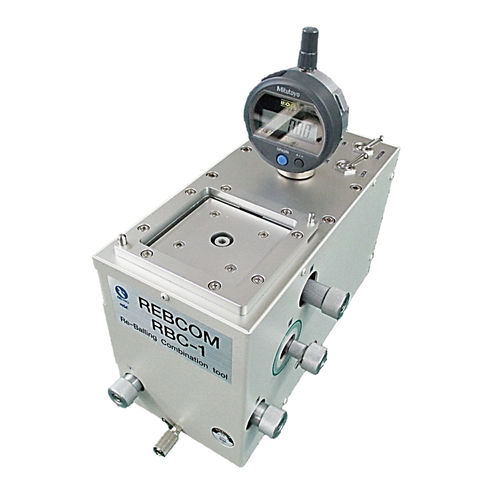

BGA rework station Rebcom RBC-1for SMD

Add to favorites

Compare this product

Characteristics

- Applications

- for BGA, for SMD

Description

"Solder paste printing before component mounting and Reballing during rework can be easily done with one unit.

One-touch positioning mechanism (Patent No.6156738)

2 diagonal guide pins on the main unit were designed to match with all accessories as the same position of 2 diagonal guide holes

to fit on the main unit including CENTERING TOOL (Patented 6156738).

With these features, it is possible to match the pad positions of a component

and the stencil holes in the X, Y, Z, and θ directions with almost no need adjustment.

However, a fine adjustment of component table can be done with high precision 0.5mm per one 360°knob rotation of XYZθ axes each individually.

There is a digital gauge comes to show Z axis the position of SMD table with digital numeric on display.

User can know the position where SMD supposes to contact to stencil and when to detach the stencil as well.

This one of the most important factor becomes a key to success when reballing.

Vacuum structure

Vacuum structure was applied to keep SMD fixed in position after centering.

2 pieces of Mask holders for printing stencil and for reballing have 2 diagonal guide holes to fit on the main unit.

Make both processes can be done highly stable without mechanical error.

The excess of solder balls can be easily collected with vacuum tube and be kept into a glass bottle properly.

VIDEO

Catalogs

Catalog 2

3 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.