- Production Machines

- Forming Machine

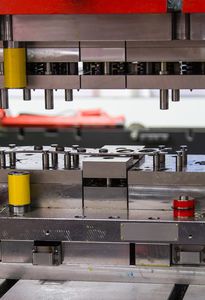

- Air sheet bending

- Mekoprint A/S

Air sheet bending aluminumISO 9001ISO 14001

Add to favorites

Compare this product

Characteristics

- Type

- air

- Treated material

- aluminum

- Certifications

- ISO 9001, ISO 14001

Description

Mekoprint has been providing customized and professional metal bending since 1954 in close cooperation with our satisfied customers.

Mekoprint has a continuous focus on acquiring the necessary competencies and up-to-date certificates, which means that the quality always in focus – our customers can therefore always expect a high quality work with delivery on time.

When it comes to sheet metal manfuacturing of large and small parts, it is not possible to avoid bending of aluminum, stainless steel, steel, copper etc.

At Mekoprint Mechanics we bend up to 3000 mm in the length.

At Mekoprint Micromechanics, we bend fine mechanics up to 1000 mm in the length.

Please contact Mekoprint for a non-binding dialogue on manufacturing of sheets, panels or fine mechanical components.

Mekoprint Micromechanics work with micro and micro mechanical components, EMI shielding and metal name plates. Such workpieces often need one or more bends to achieve the desired shape.

Mekoprint’s machinery includes, amongst other things, Trumpf Trubend 7036 machines that ensure a fast, accurate and effective result for both small and medium sized workpieces.

Mekoprint Micromechanics bends parts in the following formats:

Material thickness: 0,1-3 mm

Bending length max. 1000 mm

Tonnes: 36

Contact Mekoprint Micromechanics for more information about manufacturing of small parts. With many years of expetise, we know how to solve your problem.

The process is carried out by placing a metal plate between an over-die which is shaped like a wedge and a sub-die which is shaped like a V. Then the two tools are pressed together around the metal plate with a large force causing a bend in the material.

Catalogs

No catalogs are available for this product.

See all of Mekoprint A/S‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.