- Machine-tools

- Machining Center

- Metal turning machining

- Mekoprint A/S

Metal turning machining industrialmedicalfor electronics

Add to favorites

Compare this product

Characteristics

- Treated material

- metal

- Applications

- industrial, medical, for electronics

- Production method

- large series, prototyping

- Other characteristics

- CNC, precision, 5-axis

- Certifications

- ISO 9001, ISO 14001

Description

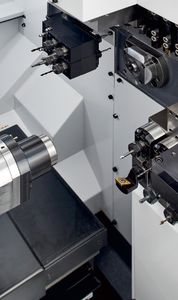

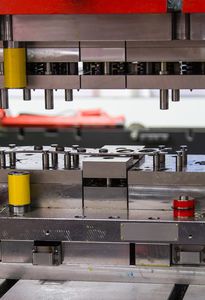

MICRO TURNING OF PRECISION TURNED PARTS

Mekoprint Chemigraphics offers micro turning of precision parts in metals and plastics, where small tolerances and superior surface finish are common demands.

Micro machining with a bar charger, makes it possible to perform micro turning around the clock. Therefore, components with the following specifications are manufactured daily:

Diameters down to 0,1 mm

Tolerances below 5µm

We have all necessary competencies in-house, to assist you all the way from the idea and concept phase to the manufacturing of prototypes and serial production – regardless of volume and complexity.

Our customers particularly operate within the areas of electronics, medico and other industrial segments with high demands – also concerning the required documentation level of the product quality.

Contact Mekoprint for a non-committal talk about micro machined parts.

PRECISION TURNED COMPONENTS MANUFACTURED WITH MICRO TURNING

Micro precision machining with micro turning

Since its founding in 1954, Mekoprint Chemigraphics has evolved from producing metal signs to becoming a supplier of micro machined parts covering a wide range of technologies that support both metal and plastics production.

In 2015 we introduced the 5-axis micro milling, which was later supplemented with micro turning.

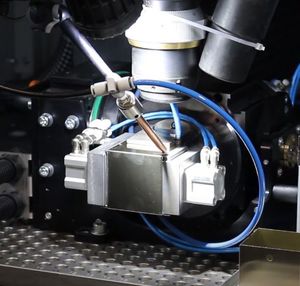

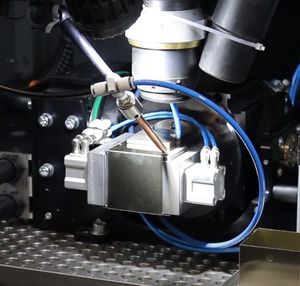

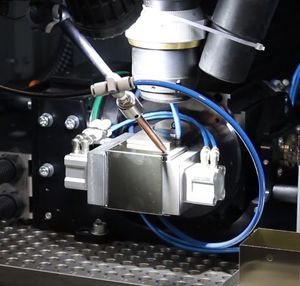

Micro turning is performed on a 7-axis high-precision lathe with a unique performance for micro machining and micro drilling of turned parts with high precision and small diameters. It has a speed of up to 15.000 rpm. on the spindles, giving the best conditions for producing the smallest diameters, for example machining of micro pins or machining of micro nozzle.

Catalogs

No catalogs are available for this product.

See all of Mekoprint A/S‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.