Laser micro-cutting steelstainless steelaluminum

Add to favorites

Compare this product

Characteristics

- Technique

- laser

- Material

- steel, stainless steel, aluminum, copper, brass, nickel, plastic

- Production method

- large series, small series

- Certifications

- ISO 14001, ISO 9001

Description

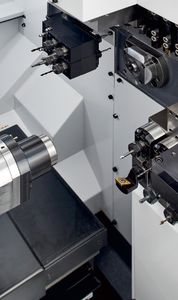

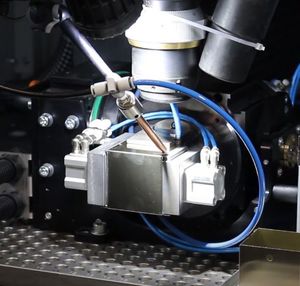

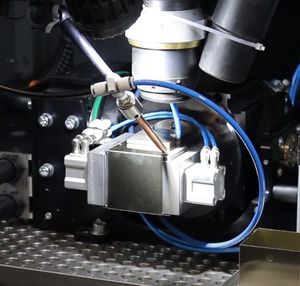

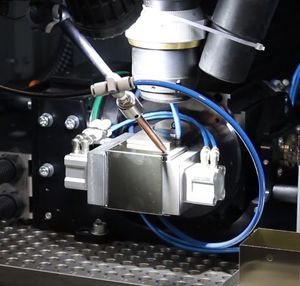

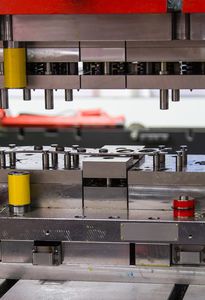

At Mekoprint we offer our customers the latest technology in micro laser machining of fine mechanical components in material thicknesses from 0.05 to 1.5 mm.

Our setup for precision laser cutting of fine mechanics is also called fiber laser cutting.

Fiber laser cutting offers several advantages, such as a minimal heat impact, high speed, and an incredible accuracy of ± 0.01 mm.

The micro laser cutting is offered as a supplement to our etching technology, most often in the designs where very high geometric precision or very narrow openings are needed in relation to the material thickness. Even smallest and very fine contours can be cut precise and with highest dynamic.

An example of this could be a laser cut trace of 0.025 mm ± 0.01 mm in 0.2 mm thick stainless springsteel.

We laser cut both large and small series sizes and even the most complex geometries, so please contact us to hear more.

MICRO LASER PROCESSING ADVANTAGES

Ideal for small and high volume manufacturing

A minimal heat impact and a high speed

Laser micro processing with an incredible accuracy

Very high geometric precision

Cutting of narrow openings and traces

Cutting of metals and plastics

Micro laser cutting, welding, drilling and micro structuring.

Catalogs

No catalogs are available for this product.

See all of Mekoprint A/S‘s catalogsRelated Searches

- Ferrous metals cutting

- ISO 9001 cutting

- CNC cutting

- Laser cutting

- Large series cutting

- Prototyping cutting

- Stainless steel cutting

- Individual cutting

- Small series cutting

- Aluminum cutting

- ISO 14001 cutting

- Copper cutting

- Brass cutting

- Plastic cutting

- Fine cutting

- Iron cutting

- Large series micro-cutting

- Micro-cutting

- Stainless steel micro-cutting

- ISO 9001 micro-cutting

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.