Laser welding copperISO 9001ISO 14001

Add to favorites

Compare this product

Characteristics

- Technique

- laser

- Material

- copper

- Certifications

- ISO 9001, ISO 14001

Description

At Mekoprint we have great expertise in micro mechanical manufacturing, therefore we also offer our customers laser micro welding of micro mechanics in very thin material using high-tech machines.

Laser micro welding is an incredibly efficient welding method that allows the welding of two different materials, for example aluminum and copper, which will normally be a difficult process. Therefore, laser welding is a serious alternative when it comes to welding fine mechanical components.

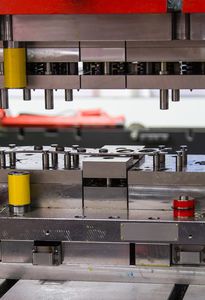

We can perform micro welding in many different materials, typically in stainless steel, nickel silver, aluminum and steel in thicknesses from 0,03 mm up to 1,0 mm.

If you need laser welding in a thicker material, please read more on laser welding for more information.

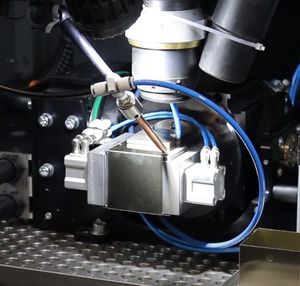

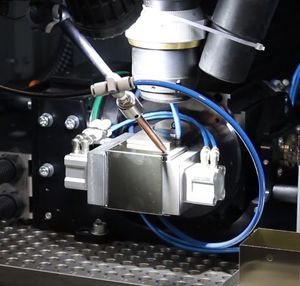

The high precision welding machinery is the type LLT MLA 500 micro laser welder, that performs micro laser welding of fine mechanics at Mekoprint.

The laser micro welding machine is with “direct drive” axes ensure a positioning accuracy of ±0,002 mm and a repetition accuracy of ±0,001 mm, which matches the absolute best on the market.

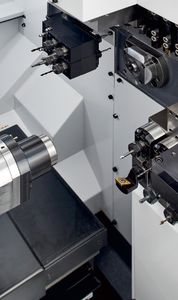

We can offer our customers complete solutions when it comes to fine mechanical products, because of the wide range of production technologies in the form of for instance punching, etching and micro laser cutting.

Catalogs

No catalogs are available for this product.

See all of Mekoprint A/S‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.