Open die stamping copperISO 9001ISO 14001

Add to favorites

Compare this product

Characteristics

- Type

- open die

- Treated material

- copper

- Certifications

- ISO 9001, ISO 14001

Description

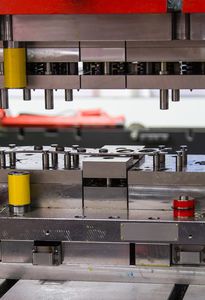

At Mekoprint, we have extensive know-how and many years of experience in high volume punching.

Therefore, we offer high-volume stamping, also known as customized progressive die stamping, of both micro precision and larger progressive die components in material thicknesses from 0.1 to 6 mm.

Progressive die stamping from coils is typically used for higher volumes with a number of units of 10,000 units per years, as the process requires investment in a fixed tool.

Regardless of which batch size and degree of complexity the customer needs, Mekoprint makes sure that each item is produced with a focus on quality, finish and compliance with tolerances.

The Progressive die stamping process takes place as an unmanned process, where the material is fed directly from a roll of material called a coil.

It is possible here to perform progressive stamping, bending, embossing, threading and deep drawing, which makes the process incredibly efficient and competitive.

Benefits

Increased production speed

Faster setup

Reduction of scrap metal

Increased repeatability

Varied geometries for the parts

Lower part costs

With a pressing force of up to 50 tonnes and 950 bpm, the machine types for micro stamping / progressive die stamping of customized progressive die stamping parts can perform precision stamping from coils made in stainless steel, steel, aluminium, nickel silver, copper, brass and tin plated coils in material thicknesses of 0.1 to 1 mm, depending on the workpiece.

Catalogs

No catalogs are available for this product.

See all of Mekoprint A/S‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.